Inline Nutrient Dosing vs Batch Mixing Illustration

Inline nutrient dosing delivers precise, real-time adjustments to nutrient concentrations, ensuring optimal plant growth and reducing waste. Batch mixing involves preparing large nutrient solutions in advance, which can lead to inconsistencies and nutrient imbalances over time. Choosing inline dosing improves efficiency and maintains consistent nutrient availability in hydroponic systems.

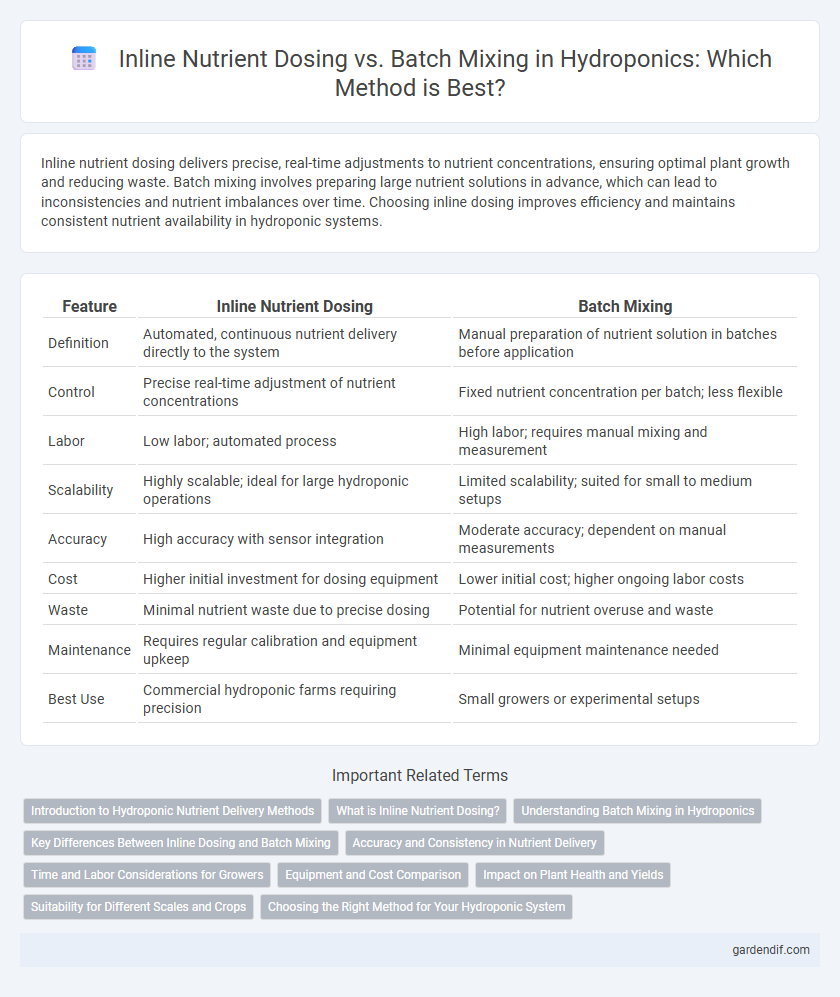

Table of Comparison

| Feature | Inline Nutrient Dosing | Batch Mixing |

|---|---|---|

| Definition | Automated, continuous nutrient delivery directly to the system | Manual preparation of nutrient solution in batches before application |

| Control | Precise real-time adjustment of nutrient concentrations | Fixed nutrient concentration per batch; less flexible |

| Labor | Low labor; automated process | High labor; requires manual mixing and measurement |

| Scalability | Highly scalable; ideal for large hydroponic operations | Limited scalability; suited for small to medium setups |

| Accuracy | High accuracy with sensor integration | Moderate accuracy; dependent on manual measurements |

| Cost | Higher initial investment for dosing equipment | Lower initial cost; higher ongoing labor costs |

| Waste | Minimal nutrient waste due to precise dosing | Potential for nutrient overuse and waste |

| Maintenance | Requires regular calibration and equipment upkeep | Minimal equipment maintenance needed |

| Best Use | Commercial hydroponic farms requiring precision | Small growers or experimental setups |

Introduction to Hydroponic Nutrient Delivery Methods

Inline nutrient dosing delivers precise, real-time nutrient adjustments directly to hydroponic systems, ensuring consistent nutrient concentration and minimizing waste. Batch mixing involves preparing large nutrient reservoirs in advance, which can lead to variability in nutrient levels and potential imbalances over time. Selecting the appropriate nutrient delivery method influences plant growth efficiency, nutrient uptake accuracy, and overall system management in hydroponic cultivation.

What is Inline Nutrient Dosing?

Inline nutrient dosing is a precise hydroponic technique where nutrients are continuously injected into the water flow, ensuring consistent and accurate delivery to plants. This method utilizes automated dosing pumps and sensors to monitor and adjust nutrient concentrations in real-time, optimizing plant growth conditions. Inline dosing minimizes nutrient waste and reduces labor compared to batch mixing, making it ideal for large-scale hydroponic systems.

Understanding Batch Mixing in Hydroponics

Batch mixing in hydroponics involves preparing a complete nutrient solution in a large container before distributing it to the plants, ensuring uniform nutrient concentration throughout the system. This method allows precise control over nutrient ratios by adjusting concentrations in one batch, minimizing fluctuations during irrigation cycles. Batch mixing is ideal for systems with consistent crop requirements and helps prevent nutrient imbalances by maintaining stable pH and EC levels before application.

Key Differences Between Inline Dosing and Batch Mixing

Inline nutrient dosing delivers precise amounts of nutrients directly to each plant container, ensuring consistent nutrient availability and reducing waste. Batch mixing involves preparing a large volume of nutrient solution in advance, which can lead to variability in nutrient concentration over time and requires storage space. Key differences include accuracy, timing of nutrient delivery, and the level of manual labor involved in monitoring and adjustments.

Accuracy and Consistency in Nutrient Delivery

Inline nutrient dosing systems provide precise and real-time control over nutrient concentration by continuously adjusting the solution strength, ensuring higher accuracy compared to batch mixing methods. Batch mixing often results in nutrient variability due to manual measurement errors and uneven blending, leading to inconsistent nutrient delivery throughout the hydroponic system. Enhanced accuracy and consistency in nutrient dosing directly improve plant growth uniformity and yield quality in hydroponic cultivation.

Time and Labor Considerations for Growers

Inline nutrient dosing significantly reduces labor by automating nutrient delivery directly to the hydroponic system, saving growers several hours weekly compared to batch mixing. Batch mixing requires manual measurement and blending of nutrients in large volumes, increasing time investment and potential for human error. Growers benefit from inline dosing through consistent nutrient levels and streamlined operations, optimizing labor efficiency and minimizing time spent on nutrient management tasks.

Equipment and Cost Comparison

Inline nutrient dosing systems offer precise control with automated pumps and sensors, reducing manual labor and minimizing nutrient waste, yet require higher initial investment in sophisticated equipment. Batch mixing relies on bulk nutrient tanks and manual blending, featuring lower upfront costs but increased labor and potential for inconsistent nutrient delivery. Long-term operational expenses favor inline dosing due to efficiency, while batch mixing may incur higher costs in labor and potential crop loss from dosing inaccuracies.

Impact on Plant Health and Yields

Inline nutrient dosing delivers precise, continuous nutrient adjustments, optimizing root zone conditions and enhancing plant health by preventing nutrient imbalances and deficiencies. Batch mixing involves preparing nutrient solutions in bulk, which can lead to inconsistencies and fluctuations in nutrient concentration, potentially stressing plants and reducing overall yields. Consistent nutrient stability from inline dosing supports higher biomass production and improved crop quality in hydroponic systems.

Suitability for Different Scales and Crops

Inline nutrient dosing systems offer precise control and are highly suitable for large-scale hydroponic operations with diverse crop requirements, allowing real-time adjustments to nutrient concentrations. Batch mixing is more practical for smaller setups or uniform crop production, providing simplicity and cost-effectiveness by preparing fixed nutrient solutions in bulk. Selection between inline dosing and batch mixing depends on operational scale, crop diversity, and the need for dynamic nutrient management in hydroponic farming.

Choosing the Right Method for Your Hydroponic System

Inline nutrient dosing delivers precise, real-time adjustments directly to hydroponic systems, enhancing nutrient consistency and reducing waste. Batch mixing involves preparing nutrient solutions in large volumes, suitable for smaller or less automated setups but may lead to variability in concentration levels. Selecting the right method depends on system scale, automation capacity, and desired nutrient control, with inline dosing preferable for commercial hydroponics and batch mixing ideal for hobbyist or small-scale growers.

Inline Nutrient Dosing vs Batch Mixing Infographic

gardendif.com

gardendif.com