Sterilizing Equipment vs Manual Cleaning Illustration

Sterilizing equipment in hydroponic systems effectively eliminates harmful pathogens and prevents cross-contamination, ensuring healthier plant growth and higher yields. Manual cleaning removes visible debris but may miss microscopic contaminants that can compromise system hygiene and crop quality. Regular sterilization enhances system longevity and reduces the risk of plant diseases compared to manual cleaning alone.

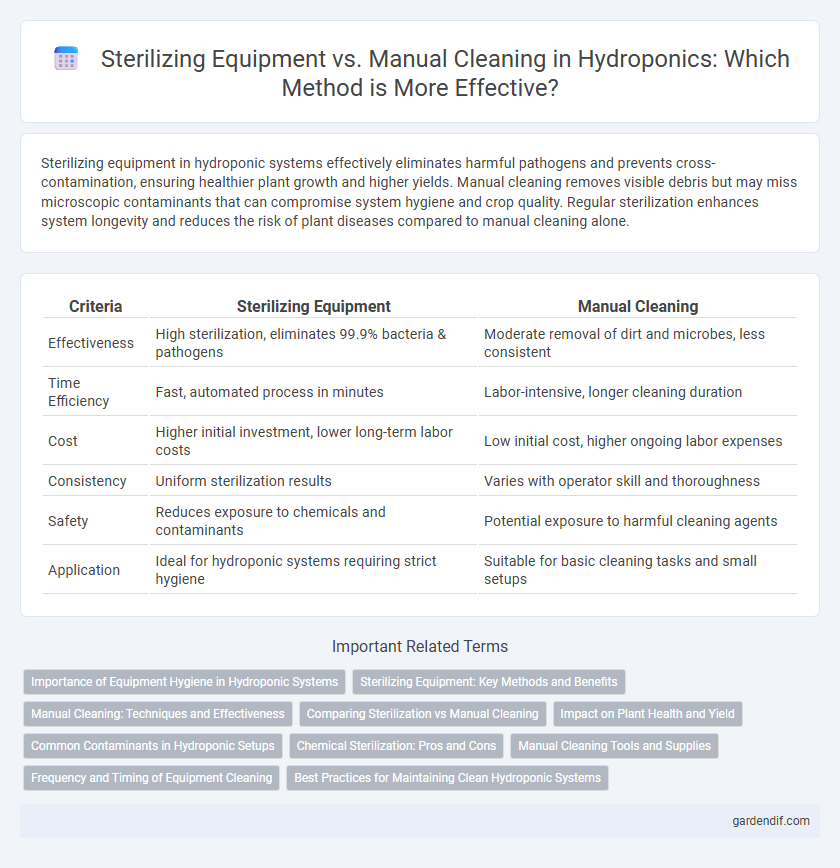

Table of Comparison

| Criteria | Sterilizing Equipment | Manual Cleaning |

|---|---|---|

| Effectiveness | High sterilization, eliminates 99.9% bacteria & pathogens | Moderate removal of dirt and microbes, less consistent |

| Time Efficiency | Fast, automated process in minutes | Labor-intensive, longer cleaning duration |

| Cost | Higher initial investment, lower long-term labor costs | Low initial cost, higher ongoing labor expenses |

| Consistency | Uniform sterilization results | Varies with operator skill and thoroughness |

| Safety | Reduces exposure to chemicals and contaminants | Potential exposure to harmful cleaning agents |

| Application | Ideal for hydroponic systems requiring strict hygiene | Suitable for basic cleaning tasks and small setups |

Importance of Equipment Hygiene in Hydroponic Systems

Sterilizing equipment in hydroponic systems is critical to prevent the spread of pathogens and algae that can compromise plant health and yield. Unlike manual cleaning, which may leave behind microbial residues, sterilization ensures thorough elimination of harmful bacteria, fungi, and viruses. Maintaining impeccable equipment hygiene optimizes nutrient delivery and promotes consistent growth, enhancing overall system efficiency.

Sterilizing Equipment: Key Methods and Benefits

Sterilizing equipment in hydroponics involves advanced methods such as UV light treatment, chemical disinfectants like hydrogen peroxide, and autoclaving to eliminate pathogens and biofilms effectively. These techniques ensure a sterile growing environment, reducing the risk of disease transmission and promoting healthy plant development. Using sterilizing equipment enhances system longevity, improves crop yields, and decreases dependency on manual labor-intensive cleaning.

Manual Cleaning: Techniques and Effectiveness

Manual cleaning in hydroponic systems involves physically scrubbing equipment with brushes and non-abrasive sponges to remove biofilm, algae, and nutrient residues. Techniques such as soaking components in diluted vinegar or hydrogen peroxide solutions enhance effectiveness by breaking down organic matter and killing pathogens without damaging materials. This hands-on approach ensures precise attention to intricate parts, maintaining system hygiene and preventing disease outbreaks in hydroponic setups.

Comparing Sterilization vs Manual Cleaning

Sterilizing equipment in hydroponic systems eliminates pathogens at a microbial level, ensuring a contamination-free environment that promotes optimal plant growth and yield. Manual cleaning removes visible debris and biofilm but may leave behind harmful microorganisms that jeopardize plant health and system longevity. Employing sterilization techniques such as UV light, ozone treatment, or chemical disinfectants offers a more effective, consistent, and scientifically proven method to maintain hydroponic system hygiene compared to manual cleaning alone.

Impact on Plant Health and Yield

Sterilizing hydroponic equipment using chemical or UV methods significantly reduces pathogen presence, limiting root diseases and promoting healthier plant growth compared to manual cleaning, which may leave harmful residues or contaminants. Consistent sterilization enhances nutrient uptake efficiency, resulting in higher crop yields and improved overall plant vitality. Studies show that hydroponic systems with sterilized tools experience up to a 30% increase in yield versus those relying solely on manual cleaning practices.

Common Contaminants in Hydroponic Setups

Sterilizing equipment in hydroponic setups effectively eliminates common contaminants such as Pythium, Fusarium, and algae, which thrive in nutrient-rich water environments. Manual cleaning often leaves behind biofilm and microbial residues that serve as breeding grounds for pathogens, increasing the risk of root rot and disease outbreaks. Using sterilization methods like hydrogen peroxide or UV light ensures a pathogen-free system, promoting healthier plant growth and higher yields.

Chemical Sterilization: Pros and Cons

Chemical sterilization in hydroponic systems effectively eliminates pathogens and biofilms, ensuring a sterile environment that reduces disease risks and promotes healthy plant growth. However, chemical residues can persist if not thoroughly rinsed, potentially harming plants and beneficial microbes, while repeated chemical use may contribute to equipment corrosion. Balancing chemical sterilization's efficacy with environmental safety and equipment longevity is essential for optimal hydroponic system maintenance.

Manual Cleaning Tools and Supplies

Manual cleaning tools and supplies in hydroponic systems are essential for maintaining a contaminant-free environment by physically removing biofilm, algae, and mineral deposits. Common supplies include brushes with nylon bristles, non-abrasive scrubbers, food-safe detergents, and sanitized sponges that prevent damage to delicate components. Consistent use of these tools ensures optimal plant health and system longevity by minimizing pathogen buildup more cost-effectively than specialized sterilizing equipment.

Frequency and Timing of Equipment Cleaning

Sterilizing equipment in hydroponic systems requires more frequent and precise timing to prevent pathogen buildup and ensure optimal plant health, typically after each crop cycle or contamination event. Manual cleaning is generally less consistent and performed on a routine basis, such as weekly or biweekly, which may allow microbial residues to persist. Implementing sterilization protocols enhances disease management by targeting equipment surfaces at critical intervals, reducing the risk of crop loss compared to manual cleaning alone.

Best Practices for Maintaining Clean Hydroponic Systems

Sterilizing equipment in hydroponic systems effectively eliminates pathogens and biofilms that manual cleaning often misses, ensuring a higher level of sanitation and reducing crop disease risks. Best practices for maintaining clean hydroponic systems include using food-safe sterilizing agents like hydrogen peroxide or bleach solutions, combined with routine manual scrubbing to remove organic debris and algae buildup. Regularly scheduled sterilization cycles paired with thorough manual cleaning extend system longevity and promote optimal plant health and growth.

Sterilizing Equipment vs Manual Cleaning Infographic

gardendif.com

gardendif.com