Commercial Nutrients vs DIY Nutrients Illustration

Commercial nutrients offer precise formulations tailored for hydroponic systems, ensuring optimal growth and consistent crop yields with minimal nutrient deficiencies. DIY nutrients allow growers to customize blends based on specific plant needs and budget constraints, providing flexibility but requiring careful monitoring to prevent imbalances. Both approaches demand a solid understanding of essential macro and micronutrients to maximize plant health and productivity in hydroponic setups.

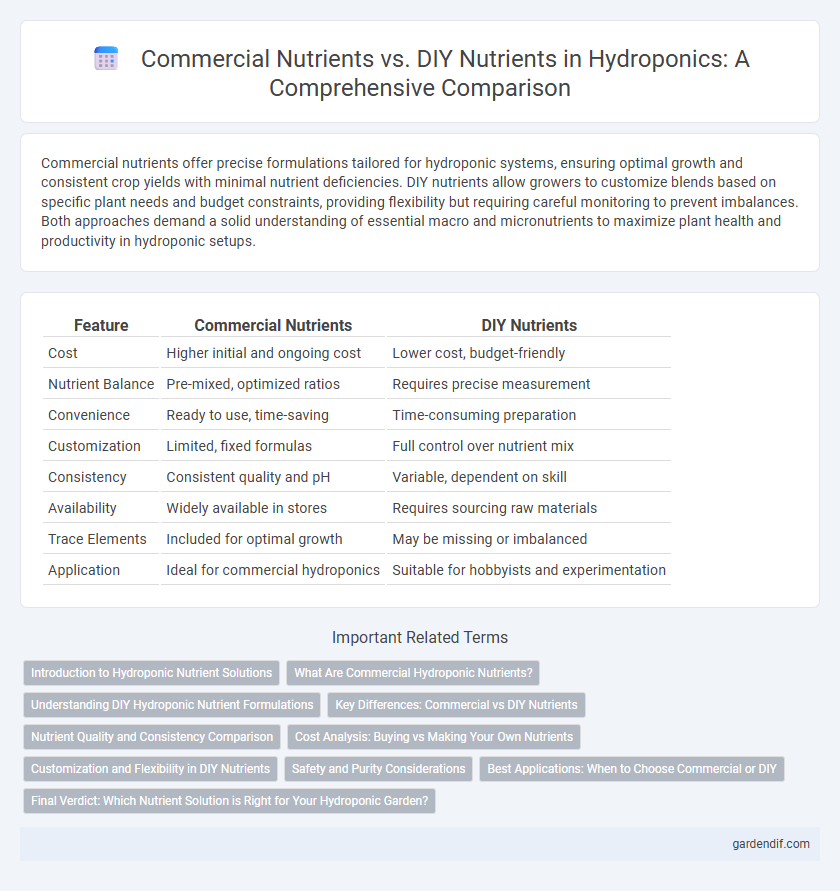

Table of Comparison

| Feature | Commercial Nutrients | DIY Nutrients |

|---|---|---|

| Cost | Higher initial and ongoing cost | Lower cost, budget-friendly |

| Nutrient Balance | Pre-mixed, optimized ratios | Requires precise measurement |

| Convenience | Ready to use, time-saving | Time-consuming preparation |

| Customization | Limited, fixed formulas | Full control over nutrient mix |

| Consistency | Consistent quality and pH | Variable, dependent on skill |

| Availability | Widely available in stores | Requires sourcing raw materials |

| Trace Elements | Included for optimal growth | May be missing or imbalanced |

| Application | Ideal for commercial hydroponics | Suitable for hobbyists and experimentation |

Introduction to Hydroponic Nutrient Solutions

Commercial hydroponic nutrient solutions offer a precise balance of essential macro and micronutrients formulated for optimal plant growth, ensuring consistent and reliable results. DIY nutrient solutions allow growers to customize nutrient ratios and concentrations based on specific crop needs and water quality, often requiring a deeper understanding of plant nutrition and chemistry. Both approaches play a crucial role in hydroponic systems, influencing plant health, yield, and overall system efficiency.

What Are Commercial Hydroponic Nutrients?

Commercial hydroponic nutrients are specially formulated liquid or powder solutions containing essential macro- and micronutrients like nitrogen, phosphorus, potassium, calcium, magnesium, iron, and trace minerals designed to support optimal plant growth in soilless systems. These commercially prepared nutrient blends ensure precise nutrient ratios, consistency, and solubility for efficient uptake by hydroponic crops, enhancing yield and overall plant health. Growers rely on commercial hydroponic nutrients to simplify nutrient management and reduce the risk of deficiencies or imbalances common in DIY nutrient mixes.

Understanding DIY Hydroponic Nutrient Formulations

DIY hydroponic nutrient formulations require precise balancing of macronutrients like nitrogen, phosphorus, and potassium, along with essential micronutrients such as iron, magnesium, and calcium to optimize plant growth. Unlike commercial nutrients, DIY blends offer customization based on specific crop needs and water quality but demand accurate measurements and knowledge of chemical interactions to prevent nutrient deficiencies or toxicities. Understanding the nutrient uptake dynamics and maintaining proper pH levels are crucial for maximizing the efficiency of homemade hydroponic solutions.

Key Differences: Commercial vs DIY Nutrients

Commercial hydroponic nutrients provide precisely balanced formulations with consistent nutrient ratios, ensuring optimal plant growth and yield. DIY nutrient solutions offer flexibility and cost savings but require careful measurement and knowledge of essential macro and micronutrients to prevent deficiencies or toxicities. The key difference lies in the reliability and convenience of commercial blends versus the customization and experimentation potential of DIY mixtures.

Nutrient Quality and Consistency Comparison

Commercial hydroponic nutrients undergo rigorous testing to ensure precise nutrient ratios and consistent quality, delivering reliable plant growth and optimal yields. DIY nutrient mixes often lack standardized formulations, leading to variable nutrient availability and potential deficiencies or toxicities. Consistent nutrient quality in commercial blends supports stable pH levels and nutrient uptake efficiency, which are critical for maximizing hydroponic crop performance.

Cost Analysis: Buying vs Making Your Own Nutrients

Commercial hydroponic nutrients offer consistent formulation and ease of use but typically come at higher per-gallon costs due to manufacturing, packaging, and brand premiums. DIY nutrient solutions, created from bulk raw salts like calcium nitrate, potassium phosphate, and magnesium sulfate, can reduce expenses by up to 50%, especially at scale, though they require precise measurements and chemical knowledge to avoid nutrient imbalances. Evaluating long-term cost efficiency hinges on the balance between initial setup complexity and the recurring expenses of pre-mixed commercial formulations in commercial hydroponic systems.

Customization and Flexibility in DIY Nutrients

DIY nutrients offer superior customization and flexibility compared to commercial nutrients, allowing growers to tailor nutrient profiles precisely to the specific growth stage and crop requirements. By adjusting ingredient ratios such as nitrogen, phosphorus, and potassium, hydroponic cultivators can optimize plant health and maximize yield while addressing unique environmental conditions. This adaptability reduces dependency on pre-formulated blends and supports sustainable, cost-effective cultivation practices.

Safety and Purity Considerations

Commercial hydroponic nutrients undergo rigorous testing to ensure safety, purity, and consistent nutrient profiles tailored for optimal plant growth, reducing the risk of contamination or nutrient imbalances. DIY nutrient solutions may lack precise formulations and quality control, potentially introducing impurities or toxic elements harmful to plants and human health. Selecting commercial nutrients minimizes risks associated with heavy metals, pathogens, and inconsistent pH levels, crucial for maintaining a safe and productive hydroponic system.

Best Applications: When to Choose Commercial or DIY

Commercial nutrients are ideal for large-scale hydroponic systems requiring precise and consistent nutrient formulations to maximize yield and minimize plant stress. DIY nutrients suit smaller or experimental setups where customization and cost control are priorities, allowing growers to tailor nutrient mixes based on specific crop needs and water quality. Selecting between commercial or DIY nutrients depends on the scale of operation, the grower's expertise, and the need for exact nutrient balance versus flexibility in formulation.

Final Verdict: Which Nutrient Solution is Right for Your Hydroponic Garden?

Commercial hydroponic nutrients provide a precisely balanced formulation of essential macro and micronutrients, ensuring optimal plant growth and consistent yields, while DIY nutrient solutions offer customization and cost savings but require in-depth knowledge of nutrient chemistry and careful monitoring of pH and EC levels. Professional growers often prefer commercial nutrients for their reliability, quality control, and ease of use, whereas hobbyists may opt for DIY mixes to tailor nutrient profiles for specific crops or growth stages. Ultimately, selecting the right nutrient solution depends on your gardening expertise, budget, crop requirements, and willingness to invest time in nutrient management for your hydroponic system.

Commercial Nutrients vs DIY Nutrients Infographic

gardendif.com

gardendif.com