Automatic Dosing vs Manual Mixing Illustration

Automatic dosing systems in hydroponics ensure precise nutrient delivery by continuously monitoring and adjusting solution concentrations, enhancing plant growth and reducing human error. Manual mixing requires careful measurement and consistent attention but offers flexibility and lower initial costs for small-scale setups. Choosing between automatic dosing and manual mixing depends on the scale of the operation, desired labor investment, and precision needs.

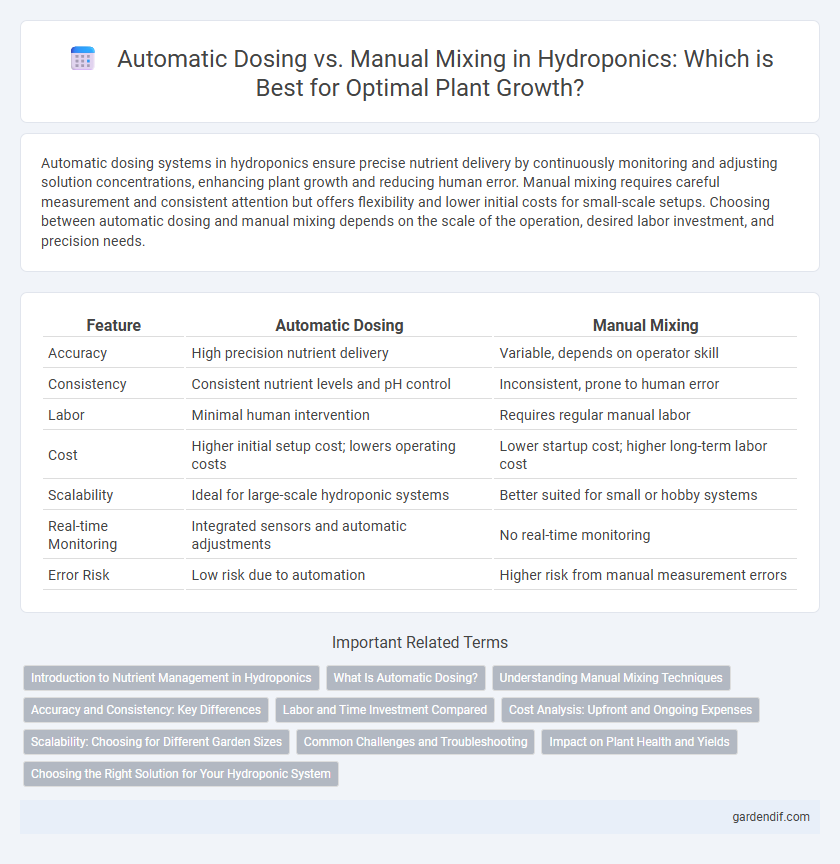

Table of Comparison

| Feature | Automatic Dosing | Manual Mixing |

|---|---|---|

| Accuracy | High precision nutrient delivery | Variable, depends on operator skill |

| Consistency | Consistent nutrient levels and pH control | Inconsistent, prone to human error |

| Labor | Minimal human intervention | Requires regular manual labor |

| Cost | Higher initial setup cost; lowers operating costs | Lower startup cost; higher long-term labor cost |

| Scalability | Ideal for large-scale hydroponic systems | Better suited for small or hobby systems |

| Real-time Monitoring | Integrated sensors and automatic adjustments | No real-time monitoring |

| Error Risk | Low risk due to automation | Higher risk from manual measurement errors |

Introduction to Nutrient Management in Hydroponics

Automatic dosing systems in hydroponics provide precise and consistent nutrient delivery by continuously monitoring pH and electrical conductivity levels, optimizing plant growth and reducing nutrient waste. Manual mixing requires careful measurement and frequent adjustments, which can lead to inconsistencies in nutrient concentration and potential imbalances. Selecting the right nutrient management method depends on factors such as crop type, scale of operation, and desired control over nutrient availability.

What Is Automatic Dosing?

Automatic dosing in hydroponics refers to a system that precisely measures and delivers nutrient solutions to plants based on real-time data and preset parameters. This technology ensures consistent nutrient balance, reduces human error, and optimizes plant growth by continuously monitoring pH, electrical conductivity (EC), and nutrient levels. Compared to manual mixing, automatic dosing enhances efficiency and accuracy, making it ideal for commercial hydroponic operations seeking to maximize yield and minimize waste.

Understanding Manual Mixing Techniques

Manual mixing techniques in hydroponics involve precisely measuring and blending nutrient solutions to ensure optimal plant growth and nutrient uptake. This method requires careful attention to the concentration of essential macro and micronutrients such as nitrogen, phosphorus, potassium, and trace elements, directly influencing plant health and yield. Mastering manual mixing allows growers to adapt nutrient formulations based on specific crop requirements and environmental conditions, enhancing overall system efficiency.

Accuracy and Consistency: Key Differences

Automatic dosing systems in hydroponics offer superior accuracy by delivering precise nutrient amounts based on real-time sensor data, minimizing human error. Manual mixing relies heavily on the grower's skill and measurement tools, often leading to variability in nutrient concentration and pH levels. Consistent nutrient delivery through automatic dosing enhances plant growth uniformity, while manual mixing can result in fluctuating nutrient availability, affecting overall crop quality.

Labor and Time Investment Compared

Automatic dosing systems in hydroponics significantly reduce labor by precisely measuring and delivering nutrients without constant human intervention, saving hours daily. Manual mixing requires substantial time investment for accurate measurement, blending, and monitoring to maintain nutrient balance. Choosing automatic dosing boosts efficiency and consistency, optimizing resource management and minimizing workforce needs.

Cost Analysis: Upfront and Ongoing Expenses

Automatic dosing systems require a higher upfront investment, often ranging from $1,000 to $5,000 depending on capacity and features, compared to manual mixing which involves minimal equipment costs such as basic measuring tools. Ongoing expenses for automatic dosing include maintenance, calibration, and occasional part replacements, while manual mixing primarily incurs labor costs and potential inaccuracies leading to nutrient waste. Over time, automatic dosing can reduce operational costs through precision and efficiency, offsetting the initial expenditure despite higher maintenance demands.

Scalability: Choosing for Different Garden Sizes

Automatic dosing systems offer superior scalability for hydroponic gardens ranging from small home setups to large commercial operations by providing precise nutrient delivery and consistent concentration levels. Manual mixing suits smaller gardens due to its lower initial cost and flexibility but becomes inefficient and prone to human error as garden size increases. Investing in automatic dosing technology ensures efficient nutrient management, reduces labor, and supports optimal plant growth in large-scale hydroponic farming.

Common Challenges and Troubleshooting

Automatic dosing systems in hydroponics often face challenges such as calibration errors, inconsistent nutrient delivery, and equipment malfunctions, requiring regular maintenance and sensor calibration to ensure accuracy. Manual mixing can lead to inconsistencies in nutrient concentrations, pH imbalances, and increased labor demands, highlighting the need for precise measurement tools and thorough training. Troubleshooting both methods involves closely monitoring nutrient solution parameters, addressing pump or valve issues in automatic systems, and verifying measurement accuracy in manual processes to maintain optimal plant growth conditions.

Impact on Plant Health and Yields

Automatic dosing systems ensure precise nutrient delivery, optimizing plant health by maintaining consistent pH and EC levels, which directly boost yields in hydroponic setups. Manual mixing often introduces variability in nutrient concentration and pH balance, increasing the risk of plant stress and uneven growth. Consistent nutrient management with automatic dosing minimizes nutrient imbalances, resulting in higher quality and more uniform crop production.

Choosing the Right Solution for Your Hydroponic System

Automatic dosing systems in hydroponics provide precise nutrient delivery, ensuring consistent pH and EC levels, which optimize plant growth and reduce human error. Manual mixing requires regular monitoring and adjustment, offering flexibility but demanding more time and skill to maintain nutrient balance. Selecting the right solution depends on system scale, budget, and desired control over nutrient management for maximizing crop yield and quality.

Automatic Dosing vs Manual Mixing Infographic

gardendif.com

gardendif.com