Batch Mixing vs Continuous Mixing Illustration

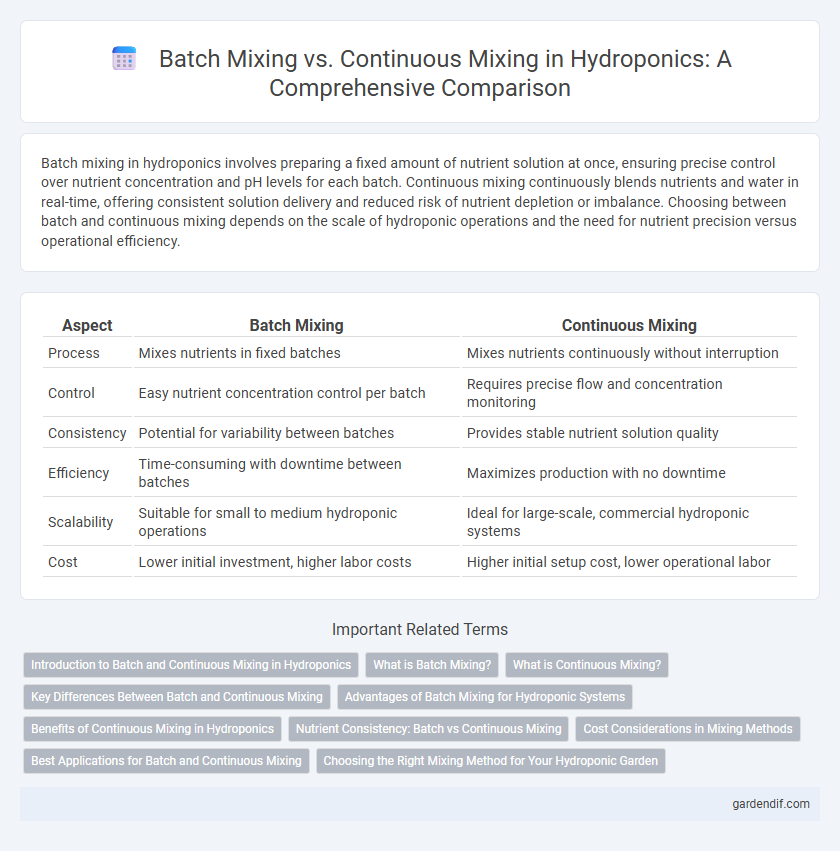

Batch mixing in hydroponics involves preparing a fixed amount of nutrient solution at once, ensuring precise control over nutrient concentration and pH levels for each batch. Continuous mixing continuously blends nutrients and water in real-time, offering consistent solution delivery and reduced risk of nutrient depletion or imbalance. Choosing between batch and continuous mixing depends on the scale of hydroponic operations and the need for nutrient precision versus operational efficiency.

Table of Comparison

| Aspect | Batch Mixing | Continuous Mixing |

|---|---|---|

| Process | Mixes nutrients in fixed batches | Mixes nutrients continuously without interruption |

| Control | Easy nutrient concentration control per batch | Requires precise flow and concentration monitoring |

| Consistency | Potential for variability between batches | Provides stable nutrient solution quality |

| Efficiency | Time-consuming with downtime between batches | Maximizes production with no downtime |

| Scalability | Suitable for small to medium hydroponic operations | Ideal for large-scale, commercial hydroponic systems |

| Cost | Lower initial investment, higher labor costs | Higher initial setup cost, lower operational labor |

Introduction to Batch and Continuous Mixing in Hydroponics

Batch mixing in hydroponics involves preparing a specific volume of nutrient solution at one time, allowing precise control over nutrient concentrations and easy adjustment for different crop requirements. Continuous mixing systems constantly blend nutrients with water in real time, supporting steady nutrient delivery and reducing labor by automating solution preparation. Both methods optimize nutrient availability but differ in operational efficiency and scalability for hydroponic farming.

What is Batch Mixing?

Batch mixing in hydroponics involves preparing nutrient solutions in predetermined volumes, allowing growers to carefully measure and combine essential macro and micronutrients before application. This method ensures precise control over nutrient concentrations, promoting optimal plant growth and reducing waste. By mixing nutrients in batches, farmers can easily adjust formulations for specific crop requirements or growth stages.

What is Continuous Mixing?

Continuous mixing in hydroponics involves the ongoing blending of nutrient solutions to maintain consistent concentration and pH levels throughout the irrigation process. This method uses automated systems to supply a steady flow of mixed nutrients, ensuring uniform distribution to plants and minimizing fluctuations that can stress crops. Continuous mixing enhances efficiency and supports optimal plant growth by delivering precise nutrient balance in real-time.

Key Differences Between Batch and Continuous Mixing

Batch mixing in hydroponic nutrient solutions involves preparing discrete quantities at specific intervals, ensuring precise control over nutrient concentration and composition for each batch. Continuous mixing maintains a steady, ongoing blend of nutrients, which supports consistent solution delivery but may reduce flexibility in adjusting nutrient ratios rapidly. Key differences include control precision, operational consistency, and scalability, with batch mixing favoring customization and continuous mixing enabling streamlined nutrient supply in large-scale hydroponic systems.

Advantages of Batch Mixing for Hydroponic Systems

Batch mixing in hydroponic systems allows precise control over nutrient concentrations, ensuring optimal plant growth and reducing the risk of nutrient imbalances. This method facilitates easier adjustments and thorough quality checks before nutrient solutions are applied, enhancing overall crop health. Batch mixing also minimizes the potential for cross-contamination and allows for tailored nutrient formulations specific to different growth stages or plant varieties.

Benefits of Continuous Mixing in Hydroponics

Continuous mixing in hydroponics ensures a consistent nutrient solution, promoting uniform plant growth and reducing the risk of nutrient imbalances. This method enhances water and nutrient use efficiency by maintaining steady concentrations, minimizing waste, and optimizing plant uptake. Automated continuous mixing systems also reduce labor costs and improve scalability for commercial hydroponic operations.

Nutrient Consistency: Batch vs Continuous Mixing

Batch mixing in hydroponics ensures precise control over nutrient concentration by preparing a fixed volume of solution, promoting uniform nutrient consistency across each batch. Continuous mixing delivers nutrients in a steady, real-time manner, allowing for immediate adjustments but risking slight fluctuations in concentration due to system dynamics. Optimal nutrient consistency depends on the specific crop requirements and system scale, with batch mixing often preferred for uniformity and continuous mixing favored for large-scale or automated setups.

Cost Considerations in Mixing Methods

Batch mixing in hydroponic systems generally involves higher initial labor and equipment costs due to separate preparation cycles, but allows precise nutrient control for smaller setups. Continuous mixing reduces labor intensity and improves nutrient consistency, offering cost efficiency for large-scale hydroponic operations through automation and reduced downtime. Evaluating system scale and labor availability is essential to optimizing cost-effectiveness between batch and continuous mixing methods.

Best Applications for Batch and Continuous Mixing

Batch mixing excels in hydroponic nutrient preparation when precise, small-scale nutrient blends are required, supporting customized nutrient solutions tailored to specific crop growth stages. Continuous mixing is ideal for large-scale hydroponic systems demanding consistent nutrient delivery and uniform solution quality over extended periods. Selecting between batch and continuous mixing depends on system size, nutrient complexity, and the need for real-time adjustment in nutrient concentration.

Choosing the Right Mixing Method for Your Hydroponic Garden

Batch mixing in hydroponic nutrient preparation allows precise control over nutrient concentrations for each cycle, ensuring consistent quality for smaller-scale gardens. Continuous mixing systems provide a steady, automated flow of nutrient solution, ideal for large-scale hydroponic operations requiring uniform distribution and efficient resource management. Selecting the right mixing method depends on garden size, automation capabilities, and the need for nutrient precision to optimize plant growth and yield.

Batch Mixing vs Continuous Mixing Infographic

gardendif.com

gardendif.com