Inline Pump vs Submersible Pump Illustration

Inline pumps provide efficient water circulation by being installed outside the hydroponic reservoir, allowing easy maintenance and reducing heat transfer to the nutrient solution. Submersible pumps operate submerged within the reservoir, offering quieter operation and compact design but may require more frequent cleaning due to direct exposure to nutrient water. Choosing between inline and submersible pumps depends on system size, noise tolerance, and ease of access for maintenance in hydroponic setups.

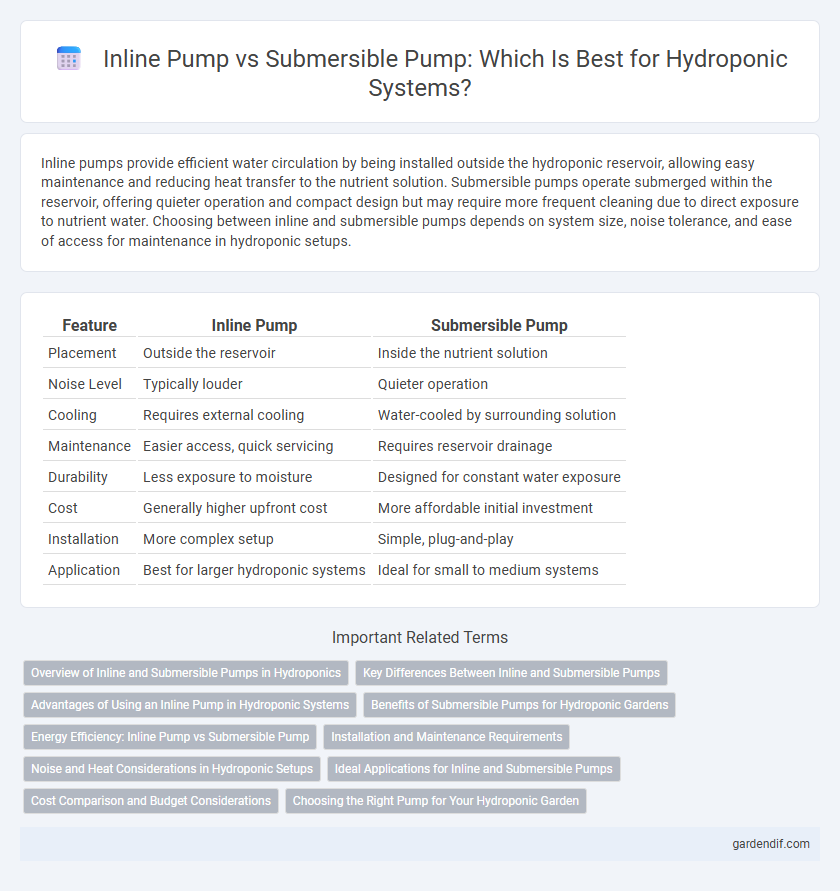

Table of Comparison

| Feature | Inline Pump | Submersible Pump |

|---|---|---|

| Placement | Outside the reservoir | Inside the nutrient solution |

| Noise Level | Typically louder | Quieter operation |

| Cooling | Requires external cooling | Water-cooled by surrounding solution |

| Maintenance | Easier access, quick servicing | Requires reservoir drainage |

| Durability | Less exposure to moisture | Designed for constant water exposure |

| Cost | Generally higher upfront cost | More affordable initial investment |

| Installation | More complex setup | Simple, plug-and-play |

| Application | Best for larger hydroponic systems | Ideal for small to medium systems |

Overview of Inline and Submersible Pumps in Hydroponics

Inline pumps and submersible pumps serve distinct roles in hydroponic systems with unique advantages. Inline pumps are installed outside the nutrient reservoir, offering easy maintenance and consistent water flow for larger systems, while submersible pumps operate submerged directly in the nutrient solution, providing efficient circulation and oxygenation for smaller setups. Choosing between them depends on system size, water flow requirements, and space constraints in hydroponic cultivation.

Key Differences Between Inline and Submersible Pumps

Inline pumps are installed outside the hydroponic system, providing easy maintenance and typically delivering higher water pressure for nutrient circulation. Submersible pumps operate submerged within the nutrient reservoir, offering quieter operation and direct water movement with lower energy consumption. Key differences include placement, noise levels, maintenance accessibility, and pressure output, which influence system design and efficiency in hydroponic setups.

Advantages of Using an Inline Pump in Hydroponic Systems

Inline pumps offer superior water circulation control and are less prone to overheating compared to submersible pumps, enhancing system reliability in hydroponic setups. Their external placement allows easier maintenance and inspection without disturbing the nutrient solution or plants. Inline pumps also typically provide higher pressure, improving nutrient delivery efficiency in larger or complex hydroponic systems.

Benefits of Submersible Pumps for Hydroponic Gardens

Submersible pumps offer significant benefits for hydroponic gardens by providing efficient water circulation directly within the nutrient solution, ensuring uniform nutrient distribution and oxygenation. Their quiet operation and energy efficiency reduce noise pollution and operational costs, enhancing the overall growing environment. Additionally, submersible pumps are less prone to overheating since they are cooled by the surrounding water, improving durability and reliability in continuous hydroponic setups.

Energy Efficiency: Inline Pump vs Submersible Pump

Inline pumps typically offer higher energy efficiency than submersible pumps due to their external placement, which reduces heat buildup and allows easier maintenance, leading to consistent performance. Submersible pumps, while effective for deep water or reservoir applications, often consume more energy as they must overcome water pressure and cooling inefficiencies. Selecting an inline pump for hydroponic systems can optimize energy usage and lower operating costs over time.

Installation and Maintenance Requirements

Inline pumps require external mounting and connection to the hydroponic system's tubing, facilitating easier access for routine maintenance and repairs without disturbing the nutrient solution. Submersible pumps are placed directly inside the nutrient reservoir, simplifying installation but complicating maintenance due to immersion in water and limited accessibility. Regular inspection and cleaning are essential for submersible pumps to prevent clogging, while inline pumps benefit from more straightforward upkeep and less frequent interference.

Noise and Heat Considerations in Hydroponic Setups

Inline pumps generate less noise and heat compared to submersible pumps, making them ideal for hydroponic systems requiring silent operation and cooler environments. Submersible pumps, while efficient at water circulation, tend to produce more heat due to motor immersion and can create additional noise within the reservoir. Choosing an inline pump enhances system stability by minimizing thermal impact and acoustic disturbance in hydroponic setups.

Ideal Applications for Inline and Submersible Pumps

Inline pumps excel in hydroponic systems requiring centralized water circulation, such as nutrient film technique (NFT) and deep water culture (DWC) setups, due to their ability to maintain consistent water pressure and flow rates from an external position. Submersible pumps are ideal for compact or reservoir-based systems where space is limited, providing efficient water circulation and aeration directly within the nutrient solution. Hydroponic growers should select inline pumps for large-scale, high-flow applications and submersible pumps for smaller, enclosed environments or easy maintenance access.

Cost Comparison and Budget Considerations

Inline pumps typically have higher upfront costs compared to submersible pumps due to their robust design and ease of maintenance in hydroponic systems. Submersible pumps are generally more budget-friendly, offering a lower initial investment and energy-efficient operation, making them ideal for small to medium-scale setups. Evaluating long-term energy consumption and maintenance expenses is crucial for optimizing overall costs in a hydroponic environment.

Choosing the Right Pump for Your Hydroponic Garden

Choosing the right pump for your hydroponic garden depends on factors such as water flow rate, noise level, and space constraints. Inline pumps offer higher pressure and are ideal for larger systems with long tubing, while submersible pumps are quieter, space-saving, and suited for smaller setups. Evaluating your garden's size and nutrient delivery needs ensures optimal water circulation and plant growth.

Inline Pump vs Submersible Pump Infographic

gardendif.com

gardendif.com