Batch Nutrient Mixing vs On-Demand Mixing Illustration

Batch nutrient mixing in hydroponics involves preparing large volumes of nutrient solution in advance, ensuring consistency and reducing daily labor, while on-demand mixing creates fresh solutions as needed, optimizing nutrient freshness and minimizing waste. Batch mixing is ideal for large-scale operations requiring uniformity, whereas on-demand mixing suits smaller setups prioritizing customization and precise nutrient control. Efficient nutrient management depends on balancing preparation time, solution stability, and system scale to maximize plant growth and resource use.

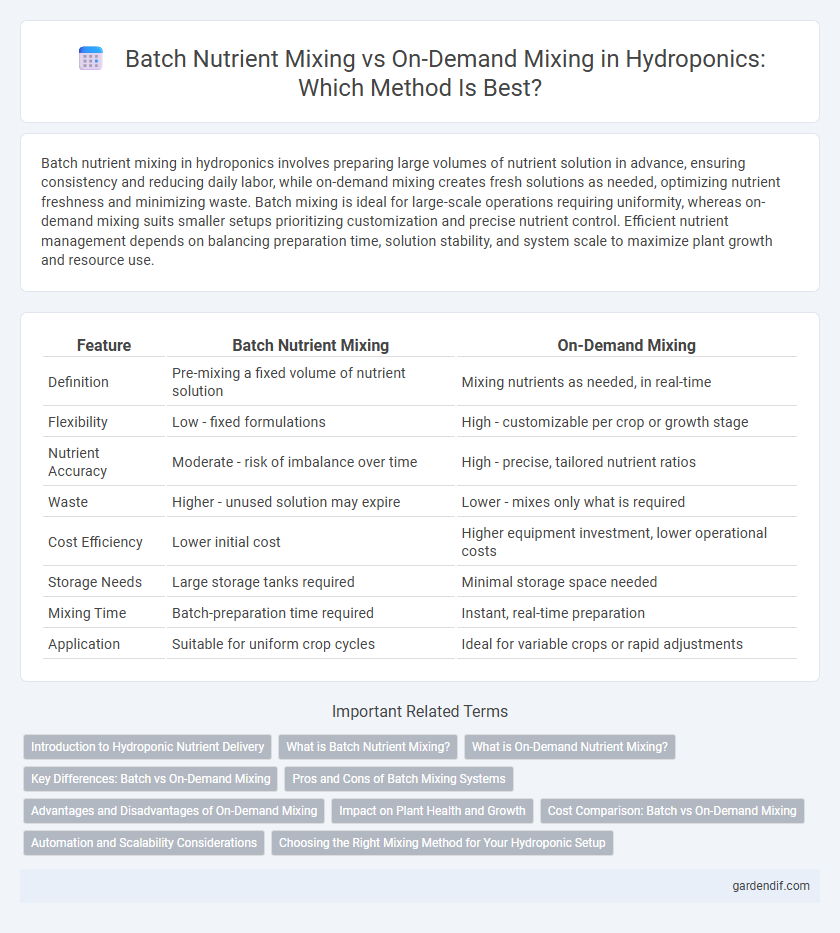

Table of Comparison

| Feature | Batch Nutrient Mixing | On-Demand Mixing |

|---|---|---|

| Definition | Pre-mixing a fixed volume of nutrient solution | Mixing nutrients as needed, in real-time |

| Flexibility | Low - fixed formulations | High - customizable per crop or growth stage |

| Nutrient Accuracy | Moderate - risk of imbalance over time | High - precise, tailored nutrient ratios |

| Waste | Higher - unused solution may expire | Lower - mixes only what is required |

| Cost Efficiency | Lower initial cost | Higher equipment investment, lower operational costs |

| Storage Needs | Large storage tanks required | Minimal storage space needed |

| Mixing Time | Batch-preparation time required | Instant, real-time preparation |

| Application | Suitable for uniform crop cycles | Ideal for variable crops or rapid adjustments |

Introduction to Hydroponic Nutrient Delivery

Batch nutrient mixing in hydroponic systems involves preparing large volumes of nutrient solution in advance, ensuring consistent composition and pH levels throughout the growth cycle. On-demand mixing allows for precise customization of nutrient blends tailored to specific plant growth stages, minimizing waste and enhancing nutrient uptake efficiency. Both methods impact water quality management, with batch mixing simplifying monitoring and on-demand mixing optimizing nutrient delivery responsiveness.

What is Batch Nutrient Mixing?

Batch nutrient mixing in hydroponics involves preparing a large volume of nutrient solution ahead of time, ensuring a consistent and homogenous mixture for multiple feeding cycles. This method allows for precise control of nutrient concentrations and pH levels by combining essential elements such as nitrogen, phosphorus, potassium, calcium, and trace minerals in a single batch. By standardizing the nutrient solution, batch mixing reduces variability, streamlines irrigation processes, and supports optimal plant growth in controlled environments.

What is On-Demand Nutrient Mixing?

On-demand nutrient mixing is a hydroponic process where nutrient solutions are prepared in real-time based on immediate plant requirements, enhancing precision and reducing waste. This method uses automated dosing systems and sensors to tailor nutrient concentrations, ensuring optimal growth conditions. It contrasts with batch mixing by delivering freshly mixed nutrients, improving efficiency and crop health.

Key Differences: Batch vs On-Demand Mixing

Batch nutrient mixing involves preparing large volumes of nutrient solution in advance, ensuring consistent composition and minimizing preparation frequency, which suits large-scale hydroponic operations. On-demand mixing creates nutrient solutions as needed, offering flexibility to adjust nutrient concentrations based on real-time plant requirements, reducing waste and preventing nutrient degradation. The key difference lies in batch mixing's efficiency for uniformity and volume versus on-demand mixing's adaptability and precision for dynamic hydroponic systems.

Pros and Cons of Batch Mixing Systems

Batch nutrient mixing systems offer consistent nutrient ratios by preparing large volumes in advance, ensuring uniformity across hydroponic crops. However, they can lead to nutrient degradation over time and lack flexibility to adjust formulas for specific plant growth stages or changing environmental conditions. The upfront time and storage requirements may also pose challenges for small-scale or dynamic hydroponic operations.

Advantages and Disadvantages of On-Demand Mixing

On-demand nutrient mixing in hydroponics allows precise customization of nutrient solutions tailored to specific crop needs, minimizing nutrient waste and reducing storage requirements. This method enables growers to respond quickly to varying plant growth stages and environmental conditions, enhancing resource efficiency and crop quality. However, it requires more advanced equipment and monitoring systems, increasing initial costs and complexity compared to batch nutrient mixing.

Impact on Plant Health and Growth

Batch nutrient mixing provides consistent nutrient availability, reducing fluctuations in pH and EC levels that can stress plants and inhibit growth. On-demand mixing allows for precise nutrient adjustments tailored to specific crop stages, optimizing nutrient uptake and promoting healthier, faster development. Both methods impact plant health by influencing nutrient stability, but on-demand mixing often results in better growth outcomes due to its adaptive nutrient delivery.

Cost Comparison: Batch vs On-Demand Mixing

Batch nutrient mixing generally reduces overall costs by allowing bulk purchasing of concentrated solutions and minimizing labor through large-scale preparation, leading to economies of scale. On-demand mixing, while offering precise nutrient customization and reduced waste, often incurs higher operational costs due to frequent preparation cycles and increased labor requirements. Choosing the optimal nutrient mixing strategy depends on balancing upfront investment with ongoing labor and material expenses in hydroponic systems.

Automation and Scalability Considerations

Batch nutrient mixing in hydroponic systems allows automation through pre-programmed dosing schedules, enabling consistent nutrient delivery and scalability for large operations with minimal manual intervention. On-demand mixing offers greater flexibility by adjusting nutrient solutions in real-time based on sensor data, optimizing resource use but requiring sophisticated automation controls to manage variability at scale. Both methods necessitate integration with automated monitoring systems to ensure precise nutrient balance and support scalable hydroponic production efficiently.

Choosing the Right Mixing Method for Your Hydroponic Setup

Batch nutrient mixing offers consistency and efficiency by preparing large volumes of nutrient solution in advance, ideal for larger hydroponic systems requiring uniformity. On-demand mixing provides flexibility and precision, allowing growers to tailor nutrient concentrations based on real-time plant needs and system feedback. Selecting the right method depends on the scale of your hydroponic setup, resource availability, and the level of control desired over nutrient delivery.

Batch Nutrient Mixing vs On-Demand Mixing Infographic

gardendif.com

gardendif.com