Manual Sorting vs Automated Sorting Illustration

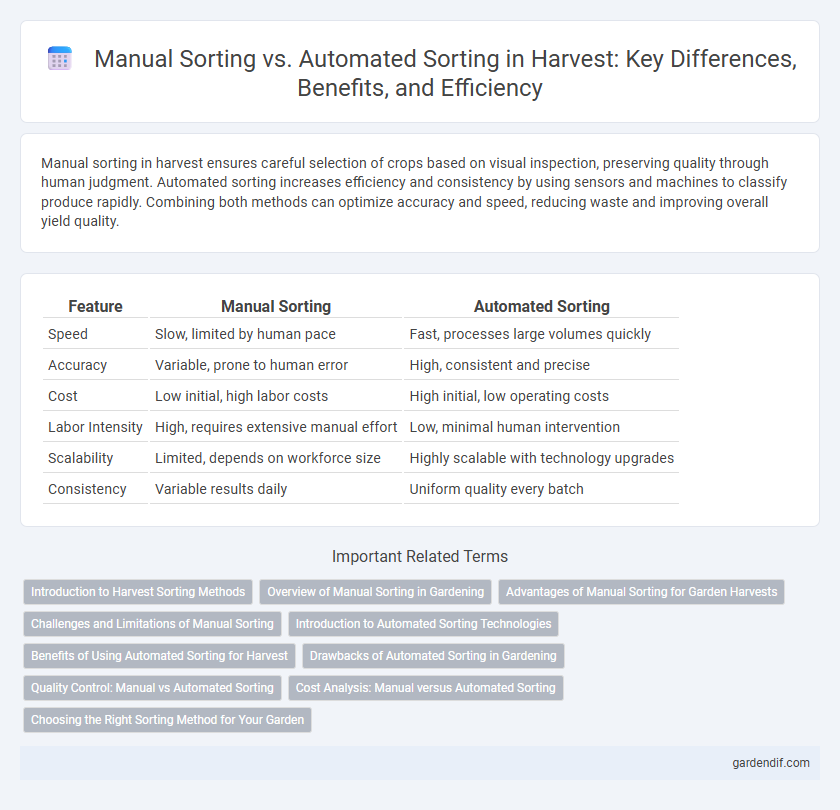

Manual sorting in harvest ensures careful selection of crops based on visual inspection, preserving quality through human judgment. Automated sorting increases efficiency and consistency by using sensors and machines to classify produce rapidly. Combining both methods can optimize accuracy and speed, reducing waste and improving overall yield quality.

Table of Comparison

| Feature | Manual Sorting | Automated Sorting |

|---|---|---|

| Speed | Slow, limited by human pace | Fast, processes large volumes quickly |

| Accuracy | Variable, prone to human error | High, consistent and precise |

| Cost | Low initial, high labor costs | High initial, low operating costs |

| Labor Intensity | High, requires extensive manual effort | Low, minimal human intervention |

| Scalability | Limited, depends on workforce size | Highly scalable with technology upgrades |

| Consistency | Variable results daily | Uniform quality every batch |

Introduction to Harvest Sorting Methods

Harvest sorting methods are essential for ensuring product quality and efficiency in agricultural processes. Manual sorting relies on human skill for detecting defects and selecting produce, offering flexibility but limited scalability. Automated sorting uses advanced technologies like machine vision and sensors to enhance speed, accuracy, and consistency in distinguishing produce quality.

Overview of Manual Sorting in Gardening

Manual sorting in gardening involves the hands-on inspection and selection of harvested crops based on size, ripeness, and quality. This traditional method allows for precise removal of unwanted debris, damaged produce, and contaminants, ensuring a higher quality yield. Although labor-intensive, manual sorting offers flexibility for small-scale gardens and specialty crops where attention to detail is crucial.

Advantages of Manual Sorting for Garden Harvests

Manual sorting in garden harvests enhances the precision of selecting ripe and high-quality fruits and vegetables, minimizing the risk of damage to delicate produce. Skilled workers can identify subtle variations in texture, color, and size that automated systems might overlook, ensuring optimal product quality. This method supports sustainable practices by reducing waste and allows for immediate removal of defective items, improving overall crop value.

Challenges and Limitations of Manual Sorting

Manual sorting in harvest processes faces significant challenges, including labor intensity, inconsistency, and slower throughput compared to automated systems. Human error can lead to variable quality and increased contamination risks, especially in large-scale operations. Limited scalability and higher operational costs further constrain manual sorting efficiency in modern agricultural workflows.

Introduction to Automated Sorting Technologies

Automated sorting technologies in harvest processing utilize advanced sensors, machine learning algorithms, and robotic arms to efficiently separate crops based on size, ripeness, and quality, significantly increasing throughput compared to manual sorting. These systems reduce human error and labor costs while improving consistency and traceability in the sorting process. Integration with real-time monitoring and data analytics enables optimized harvest yields and better supply chain management.

Benefits of Using Automated Sorting for Harvest

Automated sorting in harvest operations increases efficiency by rapidly processing large volumes of produce with consistent accuracy, reducing human error and labor costs. Advanced sensors and AI technology enable precise identification and separation of high-quality crops from damaged or unripe items, enhancing overall yield quality. Integration of automated sorting systems supports real-time data collection and traceability, optimizing supply chain management and minimizing waste.

Drawbacks of Automated Sorting in Gardening

Automated sorting systems in gardening often struggle with accurately identifying and separating delicate or irregularly shaped crops, leading to increased damage or waste. High initial costs and complex maintenance requirements can make these technologies inaccessible for small-scale growers. Moreover, automated solutions may lack the adaptability needed to handle varied harvest conditions, reducing overall efficiency.

Quality Control: Manual vs Automated Sorting

Manual sorting in harvest quality control enables precise inspection and selection of produce based on subtle visual cues such as color, shape, and texture, ensuring high standards for premium products. Automated sorting leverages advanced sensors and machine learning algorithms to quickly categorize large volumes of crops, enhancing throughput while maintaining consistent quality by detecting defects invisible to the human eye. Both methods contribute to improved yield and reduced waste, yet combining human expertise with automated systems often results in optimal quality assurance during post-harvest processing.

Cost Analysis: Manual versus Automated Sorting

Manual sorting incurs higher labor costs due to the need for extensive human labor and training, affecting overall operational expenses. Automated sorting systems require significant upfront investment in machinery and technology but reduce long-term labor costs and increase throughput efficiency. Over time, automation offers a favorable return on investment by minimizing errors and enhancing productivity compared to manual sorting methods.

Choosing the Right Sorting Method for Your Garden

Choosing the right sorting method for your garden during harvest depends on crop volume, labor availability, and accuracy requirements. Manual sorting provides precise selection for delicate fruits and small-scale gardens, ensuring minimal damage and high-quality produce. Automated sorting suits larger operations with consistent crop size and shape, enhancing speed and efficiency while reducing labor costs.

Manual Sorting vs Automated Sorting Infographic

gardendif.com

gardendif.com