Field sorting vs post-harvest sorting Illustration

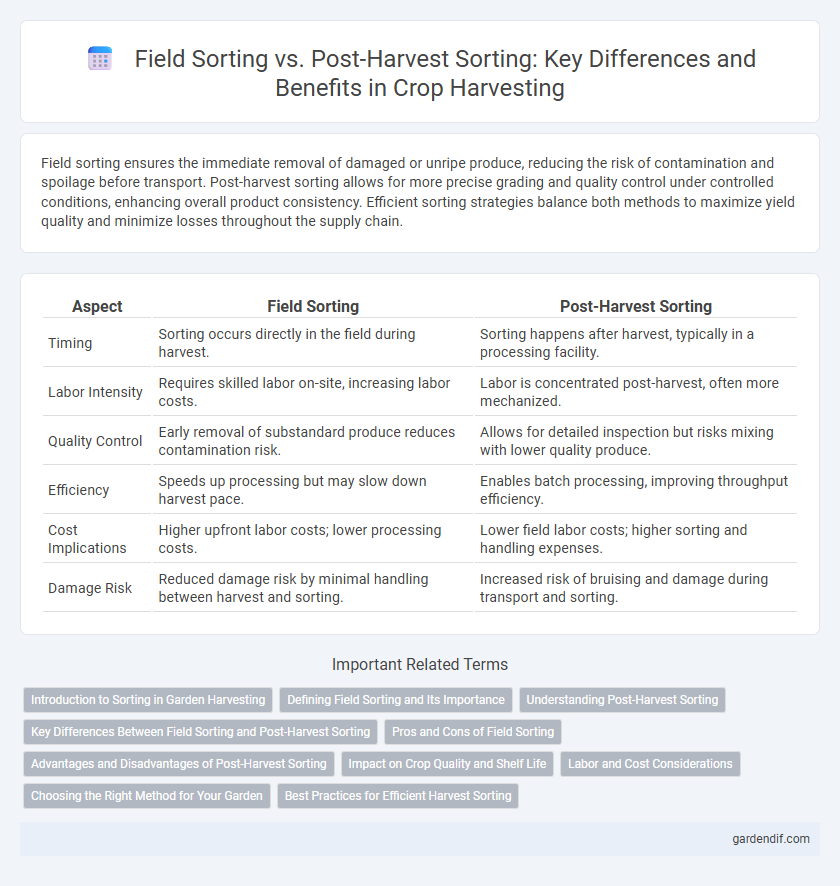

Field sorting ensures the immediate removal of damaged or unripe produce, reducing the risk of contamination and spoilage before transport. Post-harvest sorting allows for more precise grading and quality control under controlled conditions, enhancing overall product consistency. Efficient sorting strategies balance both methods to maximize yield quality and minimize losses throughout the supply chain.

Table of Comparison

| Aspect | Field Sorting | Post-Harvest Sorting |

|---|---|---|

| Timing | Sorting occurs directly in the field during harvest. | Sorting happens after harvest, typically in a processing facility. |

| Labor Intensity | Requires skilled labor on-site, increasing labor costs. | Labor is concentrated post-harvest, often more mechanized. |

| Quality Control | Early removal of substandard produce reduces contamination risk. | Allows for detailed inspection but risks mixing with lower quality produce. |

| Efficiency | Speeds up processing but may slow down harvest pace. | Enables batch processing, improving throughput efficiency. |

| Cost Implications | Higher upfront labor costs; lower processing costs. | Lower field labor costs; higher sorting and handling expenses. |

| Damage Risk | Reduced damage risk by minimal handling between harvest and sorting. | Increased risk of bruising and damage during transport and sorting. |

Introduction to Sorting in Garden Harvesting

Field sorting involves separating fruits and vegetables directly in the garden during harvest, ensuring only quality produce is collected and reducing post-harvest handling. Post-harvest sorting occurs after the produce is transported from the field, focusing on further selection to remove damaged or unripe items to enhance storage and market value. Effective sorting practices optimize freshness, minimize waste, and improve overall yield quality for garden harvesting operations.

Defining Field Sorting and Its Importance

Field sorting involves the selection and removal of damaged or unripe crops directly in the field before harvest, ensuring only high-quality produce is collected. This process reduces contamination and spoilage during transportation and storage, improving overall crop quality and market value. Implementing effective field sorting minimizes post-harvest losses and enhances supply chain efficiency.

Understanding Post-Harvest Sorting

Post-harvest sorting involves grading and separating crops after harvesting to ensure quality, remove damaged produce, and enhance market value. This process utilizes criteria such as size, color, weight, and ripeness, which helps in reducing losses during storage and transportation. Effective post-harvest sorting contributes significantly to food safety standards and consumer satisfaction by delivering uniform and high-quality products.

Key Differences Between Field Sorting and Post-Harvest Sorting

Field sorting involves the immediate selection and removal of damaged or inferior crops directly in the field, enabling early quality control and reducing contamination risks. Post-harvest sorting occurs after the crops are harvested, focusing on further grading, cleaning, and categorizing produce to meet market standards. Key differences lie in timing, precision, and scope, with field sorting emphasizing rapid, preliminary selection and post-harvest sorting ensuring detailed quality assessment and packaging readiness.

Pros and Cons of Field Sorting

Field sorting allows immediate removal of damaged or inferior crops, reducing post-harvest losses and minimizing storage costs. However, it demands significant labor intensity and skilled personnel to accurately assess produce quality under variable field conditions. This method may lead to inconsistent sorting outcomes due to environmental factors like lighting and weather, affecting overall product uniformity.

Advantages and Disadvantages of Post-Harvest Sorting

Post-harvest sorting enhances product quality by allowing thorough inspection and removal of damaged or inferior produce, reducing waste and improving market value. However, it can increase labor costs and require additional storage facilities, potentially leading to delays that affect freshness. Despite these challenges, post-harvest sorting enables better consistency in packaging and meets export standards more effectively than field sorting.

Impact on Crop Quality and Shelf Life

Field sorting immediately after harvest helps reduce the risk of contamination and mechanical damage, preserving the initial quality and extending shelf life by removing damaged or diseased produce early. Post-harvest sorting, conducted in controlled environments, allows for more precise grading based on ripeness, size, and external defects, which optimizes storage conditions and further prolongs shelf life. Combining both methods enhances overall crop quality, minimizes losses, and ensures better marketability during distribution.

Labor and Cost Considerations

Field sorting reduces labor costs by eliminating the need for extensive handling and transportation of produce to sorting facilities, streamlining the harvesting process. Post-harvest sorting requires additional labor for collection, sorting, and packaging, increasing operational expenses and prolonging the time to market. Choosing between field and post-harvest sorting depends on crop type, scale of operation, and available workforce, with field sorting offering efficiency for labor-intensive crops and post-harvest sorting providing quality control benefits.

Choosing the Right Method for Your Garden

Field sorting involves selecting and removing damaged or unripe crops directly in the garden, ensuring only high-quality produce is harvested. Post-harvest sorting takes place after harvesting, allowing for more thorough inspection and grading based on size, color, and ripeness to maximize market value. Choosing the right method depends on garden size, crop type, and labor availability, with field sorting reducing transport of low-quality produce and post-harvest sorting enhancing overall yield quality.

Best Practices for Efficient Harvest Sorting

Field sorting involves the initial selection and removal of substandard crops directly in the field to reduce damage during transport, while post-harvest sorting takes place after harvesting to further grade produce by size, quality, and ripeness. Best practices for efficient harvest sorting include training workers to recognize defects early, using standardized grading criteria, and employing automated sorting technologies to increase accuracy and speed. Combining field and post-harvest sorting minimizes waste, enhances product quality, and optimizes supply chain efficiency.

Field sorting vs post-harvest sorting Infographic

gardendif.com

gardendif.com