Fresh Market Harvest vs Processing Harvest Illustration

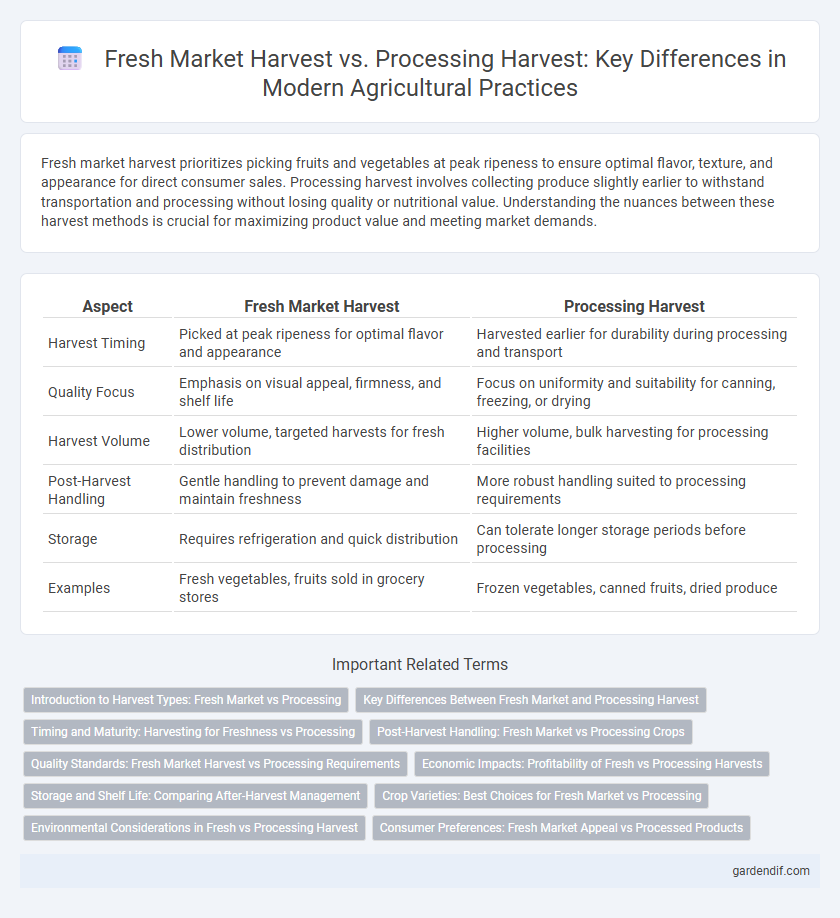

Fresh market harvest prioritizes picking fruits and vegetables at peak ripeness to ensure optimal flavor, texture, and appearance for direct consumer sales. Processing harvest involves collecting produce slightly earlier to withstand transportation and processing without losing quality or nutritional value. Understanding the nuances between these harvest methods is crucial for maximizing product value and meeting market demands.

Table of Comparison

| Aspect | Fresh Market Harvest | Processing Harvest |

|---|---|---|

| Harvest Timing | Picked at peak ripeness for optimal flavor and appearance | Harvested earlier for durability during processing and transport |

| Quality Focus | Emphasis on visual appeal, firmness, and shelf life | Focus on uniformity and suitability for canning, freezing, or drying |

| Harvest Volume | Lower volume, targeted harvests for fresh distribution | Higher volume, bulk harvesting for processing facilities |

| Post-Harvest Handling | Gentle handling to prevent damage and maintain freshness | More robust handling suited to processing requirements |

| Storage | Requires refrigeration and quick distribution | Can tolerate longer storage periods before processing |

| Examples | Fresh vegetables, fruits sold in grocery stores | Frozen vegetables, canned fruits, dried produce |

Introduction to Harvest Types: Fresh Market vs Processing

Fresh Market Harvest involves picking fruits and vegetables at peak ripeness to preserve optimal taste, texture, and nutritional value for direct consumer sale, emphasizing quality and appearance. Processing Harvest targets crops destined for transformation into products like canned, frozen, or dried goods, prioritizing uniformity, durability, and higher volume for efficient handling and extended shelf life. Understanding these distinct harvest types is crucial for tailoring harvest timing, techniques, and post-harvest management to meet specific market demands and maximize crop value.

Key Differences Between Fresh Market and Processing Harvest

Fresh market harvest involves picking crops at peak ripeness to ensure optimal flavor, texture, and appearance for direct consumer sale. Processing harvest selects crops based on uniform size and quality standards suitable for freezing, canning, or other preservation methods, often allowing harvest at different maturity stages. Key differences include timing of harvest, criteria for crop quality, and intended end-use, with fresh market prioritizing immediate consumption and processing harvest focusing on durability and shelf life.

Timing and Maturity: Harvesting for Freshness vs Processing

Harvest timing for fresh market produce is critical, emphasizing peak maturity to maximize flavor, texture, and shelf life, typically requiring early morning pickings to preserve freshness. Processing harvests prioritize uniformity and optimal maturity for efficient handling and product quality, often allowing for wider harvesting windows compared to fresh market crops. Proper timing ensures fresh market crops meet consumer expectations for immediate consumption, while processing crops are optimized for preservation and subsequent manufacturing processes.

Post-Harvest Handling: Fresh Market vs Processing Crops

Fresh market harvest emphasizes gentle post-harvest handling techniques such as careful sorting, cooling, and packaging to preserve visual quality and extend shelf life, while processing crops undergo more rigorous steps like mechanical sorting and blanching to prepare for industrial use. Temperature management is critical for fresh market produce to maintain freshness and reduce microbial growth, whereas processing crops prioritize rapid removal from the field and immediate processing to prevent enzymatic degradation. Effective post-harvest handling strategies tailored to each harvest type minimize losses and optimize product quality for their respective end uses.

Quality Standards: Fresh Market Harvest vs Processing Requirements

Fresh Market Harvest demands stringent quality standards emphasizing appearance, texture, and flavor to meet consumer expectations for freshness and visual appeal. Processing Harvest prioritizes uniformity and durability, ensuring crops withstand mechanical handling and maintain quality through storage and processing stages. Both harvest types require tailored grading and inspection protocols to optimize product suitability and market value.

Economic Impacts: Profitability of Fresh vs Processing Harvests

Fresh market harvests generally command higher prices per unit due to consumer preference for quality and appearance, driving greater profitability for growers focused on premium produce. Processing harvests yield lower market prices but benefit from bulk sales and reduced waste through industrial-grade tolerance, stabilizing income during market fluctuations. Economic impacts hinge on supply chain efficiencies, crop varieties, and market demand, influencing profit margins between fresh and processing harvest strategies.

Storage and Shelf Life: Comparing After-Harvest Management

Fresh Market Harvest demands meticulous storage conditions such as controlled temperature and humidity to maintain maximum freshness and extend shelf life, typically lasting 7 to 14 days under optimal refrigeration. Processing Harvest crops undergo different post-harvest treatments like blanching and freezing, which significantly enhance storage duration by reducing enzymatic activity and microbial growth, allowing shelf life extension up to several months. Effective after-harvest management tailored to each harvest type is crucial to minimize spoilage, preserve quality, and optimize supply chain efficiency.

Crop Varieties: Best Choices for Fresh Market vs Processing

Fresh market harvest favors crop varieties with superior appearance, flavor, and texture, such as crisp lettuce and sweet tomatoes, ensuring consumer appeal and shelf life. Processing harvest prioritizes varieties with consistent size, higher sugar content, or sturdier structure, like round tomatoes and starchy potatoes, to optimize efficiency and product quality during canning or freezing. Selecting the right crop varieties aligns harvest timing and handling practices with end-use requirements, maximizing value for both fresh consumption and industrial processing.

Environmental Considerations in Fresh vs Processing Harvest

Fresh market harvest prioritizes minimizing pesticide residues and maintaining soil health through reduced chemical use to ensure high-quality produce for direct consumption. Processing harvest focuses on maximizing yield and reducing post-harvest losses, often involving faster harvesting techniques that may increase energy consumption and water use. Environmental considerations differ as fresh market harvest emphasizes sustainability and reduced environmental impact, while processing harvest balances efficiency with resource-intensive practices.

Consumer Preferences: Fresh Market Appeal vs Processed Products

Fresh market harvests prioritize visual quality, texture, and taste, aligning with consumer preferences for vibrant, ready-to-eat produce. Processing harvests focus on consistency, shelf life, and suitability for freezing or canning, catering to consumers seeking convenience and long-term storage. Consumer demand increasingly influences harvest timing and methods to balance freshness with product stability in processed goods.

Fresh Market Harvest vs Processing Harvest Infographic

gardendif.com

gardendif.com