Recirculating System vs Run-to-Waste System Illustration

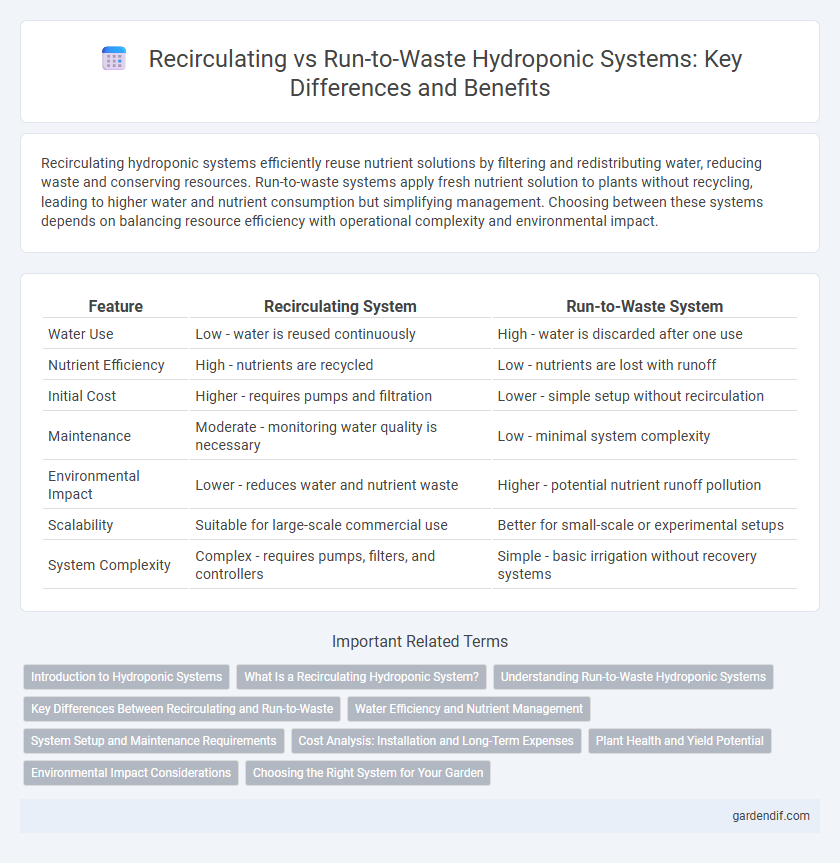

Recirculating hydroponic systems efficiently reuse nutrient solutions by filtering and redistributing water, reducing waste and conserving resources. Run-to-waste systems apply fresh nutrient solution to plants without recycling, leading to higher water and nutrient consumption but simplifying management. Choosing between these systems depends on balancing resource efficiency with operational complexity and environmental impact.

Table of Comparison

| Feature | Recirculating System | Run-to-Waste System |

|---|---|---|

| Water Use | Low - water is reused continuously | High - water is discarded after one use |

| Nutrient Efficiency | High - nutrients are recycled | Low - nutrients are lost with runoff |

| Initial Cost | Higher - requires pumps and filtration | Lower - simple setup without recirculation |

| Maintenance | Moderate - monitoring water quality is necessary | Low - minimal system complexity |

| Environmental Impact | Lower - reduces water and nutrient waste | Higher - potential nutrient runoff pollution |

| Scalability | Suitable for large-scale commercial use | Better for small-scale or experimental setups |

| System Complexity | Complex - requires pumps, filters, and controllers | Simple - basic irrigation without recovery systems |

Introduction to Hydroponic Systems

Recirculating hydroponic systems continuously recycle nutrient solutions, minimizing water and nutrient waste while maintaining optimal plant growth conditions. In contrast, run-to-waste systems deliver nutrient solution once to the plants and then discard the excess, resulting in higher resource consumption but simpler system design. Understanding these systems' operational differences is crucial for optimizing hydroponic cultivation efficiency and sustainability.

What Is a Recirculating Hydroponic System?

A recirculating hydroponic system continuously reuses nutrient-rich water by circulating it through the plant roots and back into a reservoir, optimizing water and nutrient efficiency. This system reduces waste and lowers overall water consumption compared to run-to-waste systems, where nutrient solution is discarded after a single pass. Key components include a reservoir, pump, grow tray, and filtration, ensuring a controlled environment with precise nutrient delivery for maximum plant growth.

Understanding Run-to-Waste Hydroponic Systems

Run-to-waste hydroponic systems deliver nutrient solution to plants once, allowing excess runoff to be discarded rather than recycled. This method reduces the risk of pathogen buildup and nutrient imbalances since fresh solution is used for each watering cycle. While less water-efficient compared to recirculating systems, run-to-waste setups offer simplicity and lower initial investment, making them suitable for smaller or beginner hydroponic operations.

Key Differences Between Recirculating and Run-to-Waste

Recirculating hydroponic systems reuse nutrient solutions by filtering and recirculating water, leading to significant water and nutrient conservation, while run-to-waste systems apply nutrient solutions once before discarding the excess, resulting in higher resource consumption and potential environmental impacts. Recirculating systems require more complex monitoring and equipment, including pumps and filters, compared to the simpler setup of run-to-waste systems. Crop yield and growth consistency tend to be better in recirculating systems due to precise nutrient management and reduced fluctuations in solution composition.

Water Efficiency and Nutrient Management

Recirculating hydroponic systems maximize water efficiency by continuously recycling nutrient solutions, reducing overall water consumption by up to 90% compared to run-to-waste systems. These systems enable precise nutrient management through real-time monitoring and adjustment, minimizing nutrient wastage and optimizing plant uptake. In contrast, run-to-waste systems use large volumes of water and nutrients that are discarded after a single use, leading to higher resource consumption and potential environmental runoff.

System Setup and Maintenance Requirements

Recirculating hydroponic systems require a closed-loop setup with pumps, reservoirs, and filtration units to continuously reuse nutrient solution, demanding consistent monitoring for pH, nutrient levels, and system sanitation to prevent algae and pathogen buildup. Run-to-waste systems involve a simpler one-way flow where nutrient solution is applied and drained without reuse, minimizing initial setup complexity but increasing water and nutrient consumption and waste disposal needs. Maintenance in recirculating setups is more intensive due to equipment cleaning and solution management, whereas run-to-waste systems primarily need regular irrigation component checks and waste nutrient management.

Cost Analysis: Installation and Long-Term Expenses

Recirculating hydroponic systems involve higher initial installation costs due to pumps, reservoirs, and filtration equipment, but they significantly reduce long-term water and nutrient expenses by recycling solution. In contrast, run-to-waste systems have lower upfront costs as they rely on simple delivery methods, yet they incur higher ongoing expenses from frequent water and fertilizer replacement. Evaluating the balance between capital investment and operational savings is crucial for optimizing the cost-effectiveness of hydroponic setups.

Plant Health and Yield Potential

Recirculating hydroponic systems maintain nutrient solution by filtering and reusing water, enhancing plant health through consistent nutrient availability and improved oxygenation, which often leads to higher yield potential. In contrast, run-to-waste systems discard excess nutrient solution after each use, reducing the risk of pathogen buildup but potentially causing nutrient imbalances that can stress plants and limit growth. Optimizing nutrient management in recirculating systems typically results in more efficient resource use and greater biomass production compared to the single-pass nature of run-to-waste setups.

Environmental Impact Considerations

Recirculating hydroponic systems significantly reduce water consumption by continuously reusing nutrient solutions, minimizing wastewater discharge and lowering environmental pollution. Run-to-waste systems consume more water and generate increased nutrient runoff, posing risks of soil and water contamination due to unfiltered waste disposal. Choosing recirculating systems supports sustainable agriculture by promoting resource efficiency and reducing the ecological footprint of hydroponic farming.

Choosing the Right System for Your Garden

Choosing the right hydroponic system depends on factors such as water efficiency, nutrient management, and crop type. Recirculating systems conserve water and nutrients by reusing the solution, making them ideal for larger gardens or areas with limited water supply. Run-to-waste systems are simpler to manage and reduce the risk of pathogen buildup, suited for small-scale or transient crops where precise nutrient control is less critical.

Recirculating System vs Run-to-Waste System Infographic

gardendif.com

gardendif.com