Manual Feeding vs Automated Feeding Illustration

Manual feeding in hydroponic systems allows precise control over nutrient delivery, enabling growers to tailor solutions based on specific plant needs and growth stages. Automated feeding streamlines the process by using sensors and timers to consistently provide nutrients, reducing labor and minimizing human error. Choosing between manual and automated feeding depends on factors such as system complexity, scale, and desired level of control.

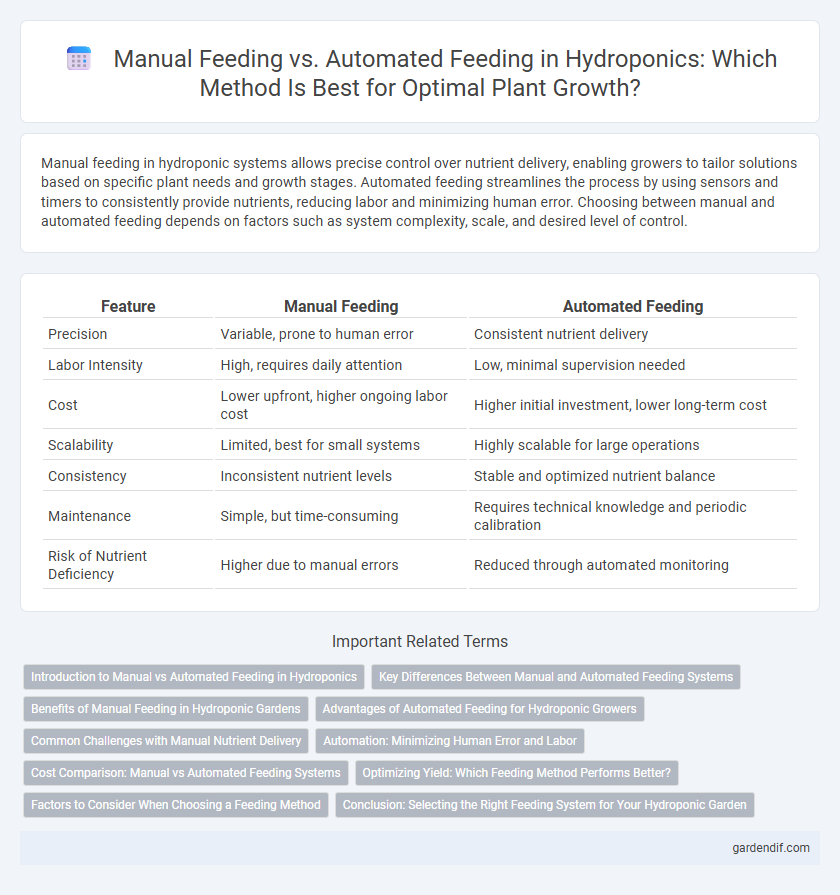

Table of Comparison

| Feature | Manual Feeding | Automated Feeding |

|---|---|---|

| Precision | Variable, prone to human error | Consistent nutrient delivery |

| Labor Intensity | High, requires daily attention | Low, minimal supervision needed |

| Cost | Lower upfront, higher ongoing labor cost | Higher initial investment, lower long-term cost |

| Scalability | Limited, best for small systems | Highly scalable for large operations |

| Consistency | Inconsistent nutrient levels | Stable and optimized nutrient balance |

| Maintenance | Simple, but time-consuming | Requires technical knowledge and periodic calibration |

| Risk of Nutrient Deficiency | Higher due to manual errors | Reduced through automated monitoring |

Introduction to Manual vs Automated Feeding in Hydroponics

Manual feeding in hydroponics involves growers directly applying nutrient solutions to plants, offering precise control over nutrient ratios and timing but requiring more labor and attention. Automated feeding systems utilize timers and pumps to deliver nutrients consistently and efficiently, reducing human error and labor costs while ensuring optimal growth conditions. Choosing between manual and automated feeding depends on factors like scale, budget, and the desired level of control in the hydroponic setup.

Key Differences Between Manual and Automated Feeding Systems

Manual feeding systems in hydroponics require growers to physically measure and distribute nutrients, demanding consistent attention and labor, which can lead to human error and uneven nutrient delivery. Automated feeding systems use sensors and timers to precisely control nutrient dosage and frequency, ensuring consistent nutrient availability and reducing labor needs. The key differences lie in accuracy, consistency, labor intensity, and scalability, with automated systems offering superior precision and efficiency for large-scale hydroponic operations.

Benefits of Manual Feeding in Hydroponic Gardens

Manual feeding in hydroponic gardens allows for precise control over nutrient delivery, enabling growers to tailor solutions to the specific needs of each plant species. This method reduces the risk of over-fertilization and nutrient imbalances, promoting healthier plant growth and higher yields. Hands-on monitoring during manual feeding also facilitates early detection of plant health issues, allowing timely interventions.

Advantages of Automated Feeding for Hydroponic Growers

Automated feeding systems in hydroponic farming provide precise nutrient delivery, ensuring optimal plant growth and reducing human error. These systems enhance resource efficiency by minimizing waste and allowing continuous monitoring and adjustments based on plant needs. Integration with sensors and smart technology promotes consistent crop quality and reduces labor costs for growers.

Common Challenges with Manual Nutrient Delivery

Manual nutrient delivery in hydroponic systems often leads to inconsistent nutrient levels due to human error and irregular feeding schedules, causing plant stress and uneven growth. The risk of overfeeding or nutrient deficiencies increases without precise measurement tools, impacting overall crop yield and quality. Frequent labor input and monitoring intensify operational costs and limit scalability compared to automated feeding solutions.

Automation: Minimizing Human Error and Labor

Automated feeding systems in hydroponics significantly reduce human error by delivering precise nutrient dosages consistently, enhancing plant health and yield. These systems utilize sensors and timers to monitor and adjust nutrient delivery, ensuring optimal growth conditions with minimal intervention. Labor requirements are lowered as automated feeding eliminates the need for manual mixing and scheduling, streamlining operations and improving efficiency in hydroponic farming.

Cost Comparison: Manual vs Automated Feeding Systems

Manual feeding systems in hydroponics require lower initial investment but involve higher long-term labor costs due to the need for regular, hands-on nutrient application. Automated feeding systems demand a higher upfront expense for equipment such as pumps, timers, and sensors but reduce labor costs and improve nutrient delivery precision over time. Cost efficiency in automated systems increases with scale and frequency of feeding, making them more cost-effective for large or commercial hydroponic operations.

Optimizing Yield: Which Feeding Method Performs Better?

Automated feeding systems in hydroponics consistently optimize yield by delivering precise nutrient dosages tailored to plant growth stages, reducing human error inherent in manual feeding. Data shows automated systems increase nutrient uptake efficiency by up to 25%, leading to faster growth cycles and higher overall production. Manual feeding may offer flexibility but generally results in inconsistent nutrient supply, limiting maximum yield potential compared to automated solutions.

Factors to Consider When Choosing a Feeding Method

When choosing between manual feeding and automated feeding in hydroponics, factors such as system size, labor availability, and budget play crucial roles. Manual feeding allows for greater control and adjustment but requires consistent labor and time investment, making it ideal for small-scale operations. Automated feeding systems enhance efficiency and precision by delivering nutrients at optimal intervals, benefiting large-scale or commercial setups with higher initial costs and maintenance requirements.

Conclusion: Selecting the Right Feeding System for Your Hydroponic Garden

Choosing the right feeding system for your hydroponic garden depends on factors such as scale, budget, and desired precision in nutrient delivery. Manual feeding offers cost-effectiveness and control for small-scale growers, while automated feeding systems provide consistent nutrient dosing and time savings ideal for larger operations. Evaluating plant growth needs and resource availability ensures optimal hydroponic nutrient management and maximized crop yields.

Manual Feeding vs Automated Feeding Infographic

gardendif.com

gardendif.com