pH Control vs EC Monitoring Illustration

Effective hydroponic systems rely on precise pH control to optimize nutrient availability and prevent nutrient lockout. Monitoring electrical conductivity (EC) provides crucial insights into the concentration of dissolved salts, ensuring plants receive the proper nutrient strength. Balancing both pH control and EC monitoring promotes healthier growth and maximizes yield in hydroponic cultivation.

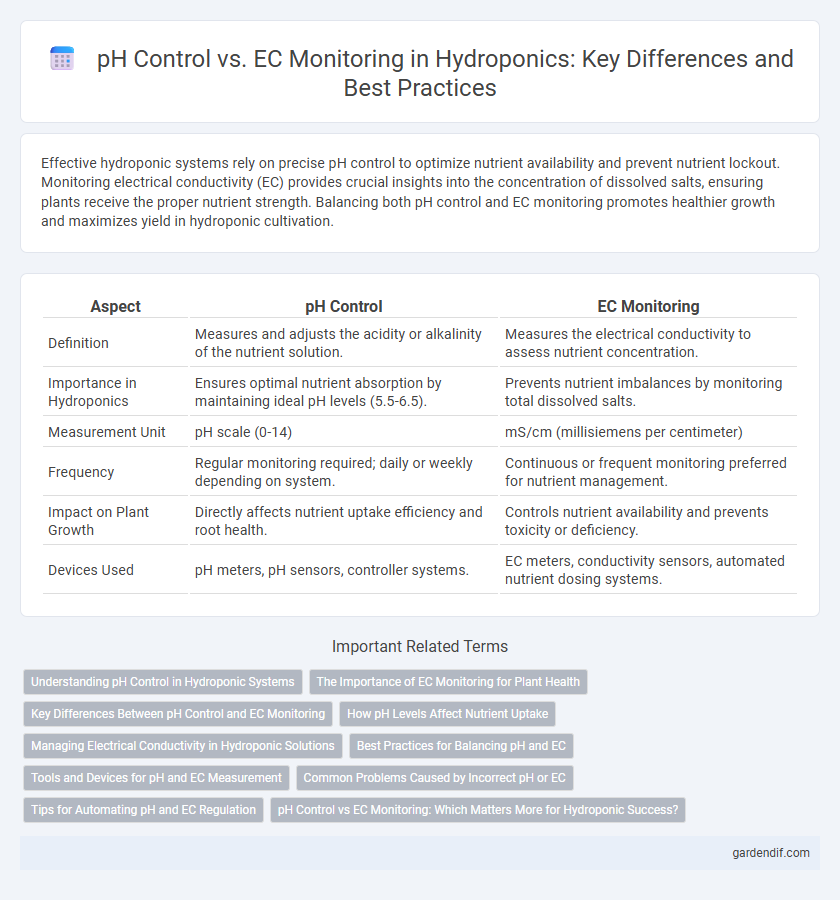

Table of Comparison

| Aspect | pH Control | EC Monitoring |

|---|---|---|

| Definition | Measures and adjusts the acidity or alkalinity of the nutrient solution. | Measures the electrical conductivity to assess nutrient concentration. |

| Importance in Hydroponics | Ensures optimal nutrient absorption by maintaining ideal pH levels (5.5-6.5). | Prevents nutrient imbalances by monitoring total dissolved salts. |

| Measurement Unit | pH scale (0-14) | mS/cm (millisiemens per centimeter) |

| Frequency | Regular monitoring required; daily or weekly depending on system. | Continuous or frequent monitoring preferred for nutrient management. |

| Impact on Plant Growth | Directly affects nutrient uptake efficiency and root health. | Controls nutrient availability and prevents toxicity or deficiency. |

| Devices Used | pH meters, pH sensors, controller systems. | EC meters, conductivity sensors, automated nutrient dosing systems. |

Understanding pH Control in Hydroponic Systems

Effective pH control in hydroponic systems is essential for nutrient availability and plant health, as it ensures the solution's acidity stays within the optimal range of 5.5 to 6.5. Monitoring pH allows growers to prevent nutrient lockout and maximize nutrient uptake efficiency, directly influencing crop yield and quality. Precise pH adjustments, using pH up or down solutions, maintain the delicate balance necessary for robust root development and overall plant growth in soilless environments.

The Importance of EC Monitoring for Plant Health

EC monitoring directly measures the electrical conductivity of the nutrient solution, providing precise data on the concentration of dissolved salts essential for plant growth. Maintaining optimal EC levels prevents nutrient imbalances that can lead to deficiencies or toxicities, ensuring robust root development and overall plant health. Unlike pH control, which manages nutrient availability indirectly, EC monitoring offers real-time insight into nutrient strength, making it crucial for effective hydroponic crop management.

Key Differences Between pH Control and EC Monitoring

pH control in hydroponics regulates the acidity or alkalinity of the nutrient solution, ensuring optimal nutrient availability for plant uptake. EC (Electrical Conductivity) monitoring measures the concentration of dissolved salts and nutrients, indicating the overall nutrient strength in the solution. The key difference lies in pH control adjusting ion balance for nutrient absorption, while EC monitoring tracks nutrient levels to prevent underfeeding or toxicity.

How pH Levels Affect Nutrient Uptake

pH levels in hydroponic systems critically influence nutrient availability and absorption by plants. Optimal pH ranges, typically between 5.5 and 6.5, ensure macronutrients like nitrogen, phosphorus, and potassium remain soluble and accessible. Deviations outside this range can lead to nutrient lockout, reducing plant growth and yield despite appropriate electrical conductivity (EC) readings.

Managing Electrical Conductivity in Hydroponic Solutions

Managing electrical conductivity (EC) in hydroponic solutions is essential for optimizing nutrient availability and plant uptake efficiency. Precise EC monitoring enables growers to maintain nutrient concentrations within ideal ranges, preventing deficiencies or toxicities that impact plant growth. Integrating EC control with pH management ensures balanced nutrient solubility and enhances overall hydroponic crop productivity.

Best Practices for Balancing pH and EC

Effective pH control and EC monitoring are essential for optimizing nutrient uptake in hydroponic systems, ensuring plant health and maximizing yield. Maintain pH levels between 5.5 and 6.5 for most hydroponic crops, adjusting with buffering agents to prevent nutrient lockout, while regularly measuring electrical conductivity (EC) to match nutrient solution concentration with plant growth stages. Implement automated sensors and data logging tools to enable precise, real-time adjustments, minimizing stress and improving overall system efficiency.

Tools and Devices for pH and EC Measurement

Precision hydroponic growth relies heavily on accurate pH control and EC monitoring, facilitated by specialized tools such as digital pH meters and conductivity sensors. High-quality pH controllers provide automatic adjustments to maintain optimal nutrient uptake, while EC meters measure the electrical conductivity of the nutrient solution to ensure proper nutrient concentration. Integration of these devices into hydroponic systems enhances real-time data accuracy, promoting healthier plant development and maximizing yield potential.

Common Problems Caused by Incorrect pH or EC

Incorrect pH levels in hydroponic systems can lead to nutrient lockout, where essential minerals become unavailable to plants, causing stunted growth and nutrient deficiencies. Improper Electrical Conductivity (EC) can result in over-fertilization or nutrient imbalances, leading to root burn or poor nutrient uptake. Maintaining precise pH and EC levels is crucial to preventing common issues such as nutrient toxicity, poor plant development, and reduced crop yields.

Tips for Automating pH and EC Regulation

Automating pH control and EC monitoring in hydroponic systems relies on integrating precise sensors with programmable controllers to maintain optimal nutrient balance and root zone conditions. Implement high-quality, durable pH and EC probes calibrated regularly to ensure accurate readings and prevent nutrient lockout or toxicity. Utilize automation software with real-time data logging and alerts that enable timely adjustments, enhancing crop yield and reducing manual labor.

pH Control vs EC Monitoring: Which Matters More for Hydroponic Success?

pH control in hydroponics ensures nutrient availability by maintaining an optimal range of 5.5 to 6.5, preventing nutrient lockout and promoting healthy plant growth. Electrical Conductivity (EC) monitoring measures the concentration of dissolved nutrients, guiding precise nutrient dosing to avoid deficiencies or toxicities. Balancing both pH control and EC monitoring is crucial for hydroponic success, with pH affecting nutrient uptake and EC indicating nutrient strength, making them complementary factors in optimized plant nutrition management.

pH Control vs EC Monitoring Infographic

gardendif.com

gardendif.com