Manual venting vs automated venting Illustration

Manual venting in greenhouses requires physical intervention to open or close vents, allowing growers to control temperature and humidity based on observation. Automated venting systems use sensors and motors to adjust vents precisely, improving climate control and reducing labor. While manual venting offers simplicity and cost savings, automated venting boosts efficiency and promotes optimal plant growth through consistent environmental regulation.

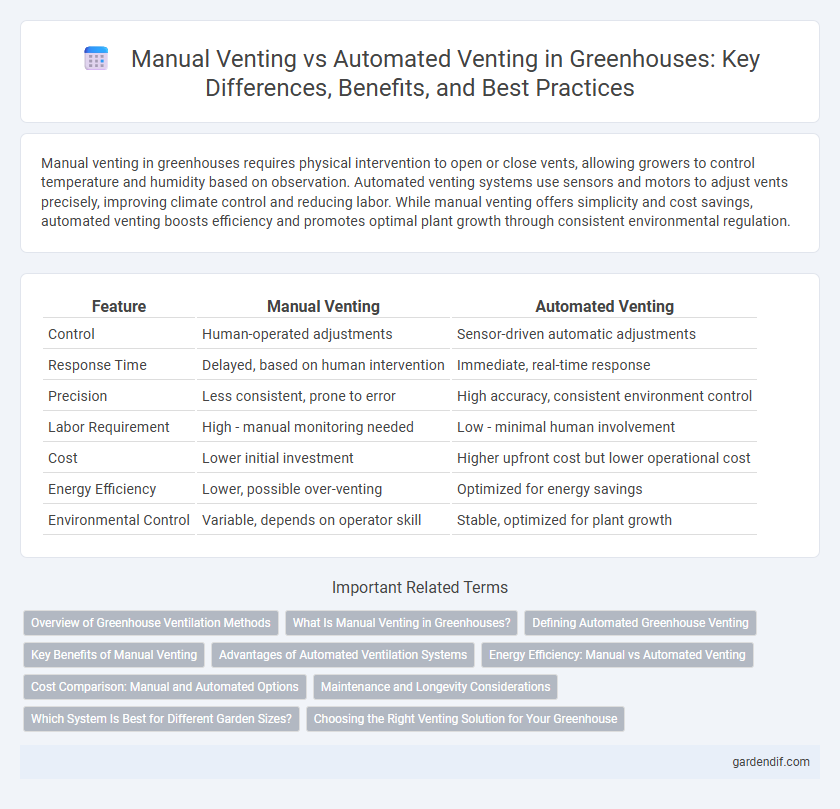

Table of Comparison

| Feature | Manual Venting | Automated Venting |

|---|---|---|

| Control | Human-operated adjustments | Sensor-driven automatic adjustments |

| Response Time | Delayed, based on human intervention | Immediate, real-time response |

| Precision | Less consistent, prone to error | High accuracy, consistent environment control |

| Labor Requirement | High - manual monitoring needed | Low - minimal human involvement |

| Cost | Lower initial investment | Higher upfront cost but lower operational cost |

| Energy Efficiency | Lower, possible over-venting | Optimized for energy savings |

| Environmental Control | Variable, depends on operator skill | Stable, optimized for plant growth |

Overview of Greenhouse Ventilation Methods

Greenhouse ventilation methods include manual venting, where vents are opened and closed by hand, and automated venting, which uses sensors and motorized systems to regulate airflow. Manual venting offers low initial costs and simplicity but requires constant human intervention and may lead to inconsistent temperature control. Automated venting improves climate stability, enhances plant growth by maintaining optimal temperature and humidity levels, and reduces labor needs.

What Is Manual Venting in Greenhouses?

Manual venting in greenhouses involves physically opening and closing vents to regulate temperature, humidity, and air circulation for optimal plant growth. It requires active human intervention, often using hand-cranks or levers to adjust roof or side vents based on environmental conditions. This method offers precise control but demands constant monitoring and labor compared to automated venting systems.

Defining Automated Greenhouse Venting

Automated greenhouse venting utilizes sensor-driven systems to regulate temperature and humidity by opening and closing vents without human intervention. This technology optimizes climate control, improving plant growth conditions and energy efficiency compared to manual venting, which relies on periodic human adjustments. Automated vents respond in real-time to environmental data, ensuring precise airflow management for healthier crops and reduced labor costs.

Key Benefits of Manual Venting

Manual venting in greenhouses offers precise control over airflow, allowing growers to respond instantly to changing weather conditions and plant needs. This method enhances energy efficiency by reducing reliance on electrical systems and lowering operational costs. Manual venting also minimizes mechanical failures, ensuring consistent ventilation without dependence on automation technology.

Advantages of Automated Ventilation Systems

Automated ventilation systems in greenhouses offer precise climate control by continuously monitoring temperature, humidity, and CO2 levels, ensuring optimal growing conditions without manual intervention. These systems enhance energy efficiency and reduce labor costs by automatically adjusting vents based on real-time environmental data. Automated venting also minimizes human error and improves plant health through consistent airflow regulation, leading to higher crop yields and reduced risk of disease.

Energy Efficiency: Manual vs Automated Venting

Manual venting in greenhouses requires human intervention for opening and closing vents, often resulting in inconsistent airflow and higher energy consumption for temperature control. Automated venting systems use sensors and timers to optimize ventilation, maintaining ideal humidity and temperature levels while minimizing energy waste. Automated venting improves energy efficiency by reducing the need for supplemental heating or cooling, leading to lower operational costs and enhanced plant growth conditions.

Cost Comparison: Manual and Automated Options

Manual venting in greenhouses involves lower upfront costs, primarily limited to basic equipment and labor expenses, making it a budget-friendly option for small-scale operations. Automated venting systems, while requiring higher initial investment for sensors, actuators, and control units, offer long-term savings through energy efficiency and reduced labor costs. Cost comparison indicates that automated venting is more economically viable for larger greenhouses with consistent climate control needs due to improved productivity and resource management.

Maintenance and Longevity Considerations

Manual venting systems require regular physical inspections and adjustments to ensure vents operate properly, increasing maintenance demands and potential wear over time. Automated venting systems utilize sensors and motorized controls to optimize airflow, reducing manual intervention and enhancing system longevity through precise operation. Proper maintenance of either system is essential, but automated systems generally extend the lifespan of vent components by minimizing mechanical strain and human error.

Which System Is Best for Different Garden Sizes?

Manual venting systems work well for small to medium-sized greenhouses where growers can easily monitor and adjust ventilation. Automated venting is ideal for larger or commercial greenhouses, ensuring consistent temperature and humidity control through sensors and motorized vents. Choosing the right system depends on garden size, budget constraints, and the need for precise environmental management.

Choosing the Right Venting Solution for Your Greenhouse

Manual venting in greenhouses offers growers direct control over airflow and temperature, making it ideal for small-scale or hobbyist operations where precise adjustments are manageable. Automated venting systems use sensors and motorized vents to maintain optimal growing conditions by reacting to temperature, humidity, and carbon dioxide levels, enhancing consistency and reducing labor. Selecting the right venting solution depends on greenhouse size, crop sensitivity, labor availability, and investment budget, with automation favored in commercial settings for improved environmental regulation and energy efficiency.

Manual venting vs automated venting Infographic

gardendif.com

gardendif.com