Controlled-release prill vs coated granule Illustration

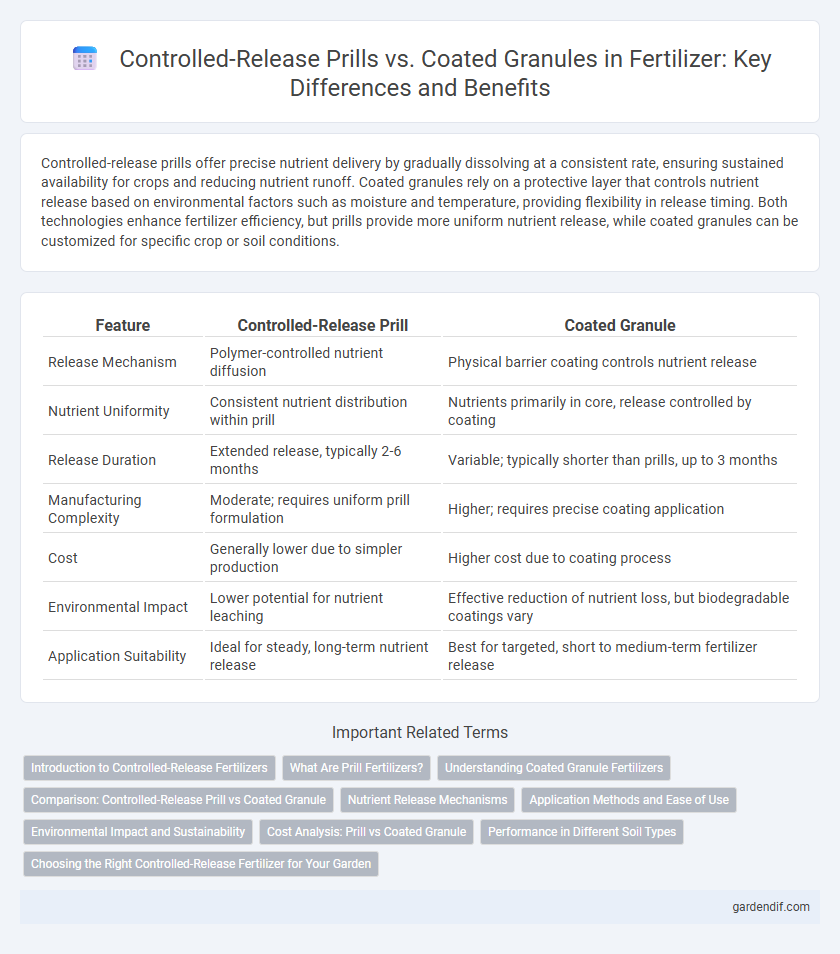

Controlled-release prills offer precise nutrient delivery by gradually dissolving at a consistent rate, ensuring sustained availability for crops and reducing nutrient runoff. Coated granules rely on a protective layer that controls nutrient release based on environmental factors such as moisture and temperature, providing flexibility in release timing. Both technologies enhance fertilizer efficiency, but prills provide more uniform nutrient release, while coated granules can be customized for specific crop or soil conditions.

Table of Comparison

| Feature | Controlled-Release Prill | Coated Granule |

|---|---|---|

| Release Mechanism | Polymer-controlled nutrient diffusion | Physical barrier coating controls nutrient release |

| Nutrient Uniformity | Consistent nutrient distribution within prill | Nutrients primarily in core, release controlled by coating |

| Release Duration | Extended release, typically 2-6 months | Variable; typically shorter than prills, up to 3 months |

| Manufacturing Complexity | Moderate; requires uniform prill formulation | Higher; requires precise coating application |

| Cost | Generally lower due to simpler production | Higher cost due to coating process |

| Environmental Impact | Lower potential for nutrient leaching | Effective reduction of nutrient loss, but biodegradable coatings vary |

| Application Suitability | Ideal for steady, long-term nutrient release | Best for targeted, short to medium-term fertilizer release |

Introduction to Controlled-Release Fertilizers

Controlled-release fertilizers (CRFs) improve nutrient efficiency by gradually releasing nutrients over time, minimizing losses from leaching and volatilization. Controlled-release prills consist of nutrient cores formed into small spherical pellets, while coated granules have a nutrient core surrounded by a polymer or resin coating that regulates nutrient diffusion. Both technologies enhance crop yield and reduce environmental impact by optimizing nutrient availability according to plant needs and soil conditions.

What Are Prill Fertilizers?

Prill fertilizers are small, uniformly shaped spherical granules formed by solidifying molten fertilizer material into compact beads. These prills provide controlled nutrient release, enhancing efficiency compared to conventional fertilizers, and are widely used in controlled-release formulations. Unlike coated granules, prills rely on their inherent material properties for gradual nutrient delivery rather than an external coating layer.

Understanding Coated Granule Fertilizers

Coated granule fertilizers consist of a nutrient-rich core enveloped by a protective coating that regulates nutrient release based on soil moisture and temperature. This coating enhances nutrient use efficiency by minimizing leaching and volatilization, ensuring sustained nutrient availability for crops. Compared to controlled-release prills, coated granules offer more uniform release patterns and improved handling characteristics, making them ideal for precision agriculture applications.

Comparison: Controlled-Release Prill vs Coated Granule

Controlled-release prills exhibit uniform nutrient release due to their spherical shape and homogeneous composition, enhancing nutrient use efficiency in crops. Coated granules, with an outer polymer or sulfur layer, provide a barrier that controls nutrient dissolution, offering flexibility in release timing based on coating thickness and environmental factors. Both forms improve fertilizer performance, but prills ensure more consistent nutrient availability, while coated granules allow for customization of release rates depending on specific crop and soil requirements.

Nutrient Release Mechanisms

Controlled-release prills release nutrients through polymer matrix diffusion, allowing a steady, predictable nutrient supply aligned with crop demand. Coated granules rely on a physical barrier, such as resin or sulfur coating, which controls nutrient dissolution rate by gradual coating degradation or cracking. Both mechanisms enhance nutrient use efficiency by minimizing leaching and volatilization losses, but prills offer more uniform nutrient release ideal for precise agronomic management.

Application Methods and Ease of Use

Controlled-release prills are typically applied using standard broadcasting equipment, ensuring uniform distribution and minimal dust generation, which enhances ease of handling in large-scale farming. Coated granules, while also compatible with common application tools, often require careful handling due to their delicate coating, which can be compromised by abrasion during transport or mechanical spreading. Both forms enable precise nutrient delivery, but prills generally offer greater operational simplicity and reduced risk of coating damage in routine fertilization practices.

Environmental Impact and Sustainability

Controlled-release prills offer enhanced environmental benefits by minimizing nutrient leaching and reducing greenhouse gas emissions compared to coated granules, which often have slower nutrient release due to thicker polymer layers. The biodegradable nature of some prill formulations supports sustainable agriculture by decreasing plastic waste accumulation in soil ecosystems. Optimizing nutrient delivery through controlled-release prills can improve crop yield efficiency while lowering the ecological footprint associated with conventional coated granules.

Cost Analysis: Prill vs Coated Granule

Controlled-release prills typically offer lower production costs compared to coated granules due to simpler manufacturing processes and reduced material usage. Coated granules incorporate specialized polymer or resin layers that increase expenses related to raw materials and equipment. Cost analysis reveals prills provide a more economical option for large-scale fertilizer application without significantly compromising nutrient release efficiency.

Performance in Different Soil Types

Controlled-release prills exhibit more consistent nutrient release across varied soil textures due to their uniform particle size and composition, enabling better root availability in sandy, loamy, and clay soils. Coated granules provide targeted nutrient delivery by adjusting coating thickness, which can enhance performance in specific soil moisture conditions but may cause uneven nutrient release in heterogeneous soils. Soil pH and microbial activity significantly influence the degradation rate of coatings, affecting nutrient availability and crop uptake efficiency for both fertilizer forms.

Choosing the Right Controlled-Release Fertilizer for Your Garden

Controlled-release prills gradually release nutrients through a porous matrix, providing consistent feeding over time, while coated granules rely on a polymer or resin layer to regulate nutrient release based on environmental factors such as moisture and temperature. Selecting the right controlled-release fertilizer depends on soil type, crop requirements, and irrigation practices; prills are ideal for uniform nutrient delivery in sandy soils, whereas coated granules offer flexibility for varying moisture conditions. Understanding the release mechanism and matching it to your garden's needs maximizes nutrient efficiency and minimizes environmental impact.

Controlled-release prill vs coated granule Infographic

gardendif.com

gardendif.com