Automated Dosing vs Manual Mixing Illustration

Automated dosing systems in hydroponics deliver precise nutrient levels consistently, reducing the risk of human error and optimizing plant growth. Manual mixing requires regular attention and expertise to maintain accurate nutrient concentrations, often leading to variability in solution quality. Investing in automated dosing enhances crop yield and efficiency by ensuring stable and tailored nutrient delivery throughout the growing cycle.

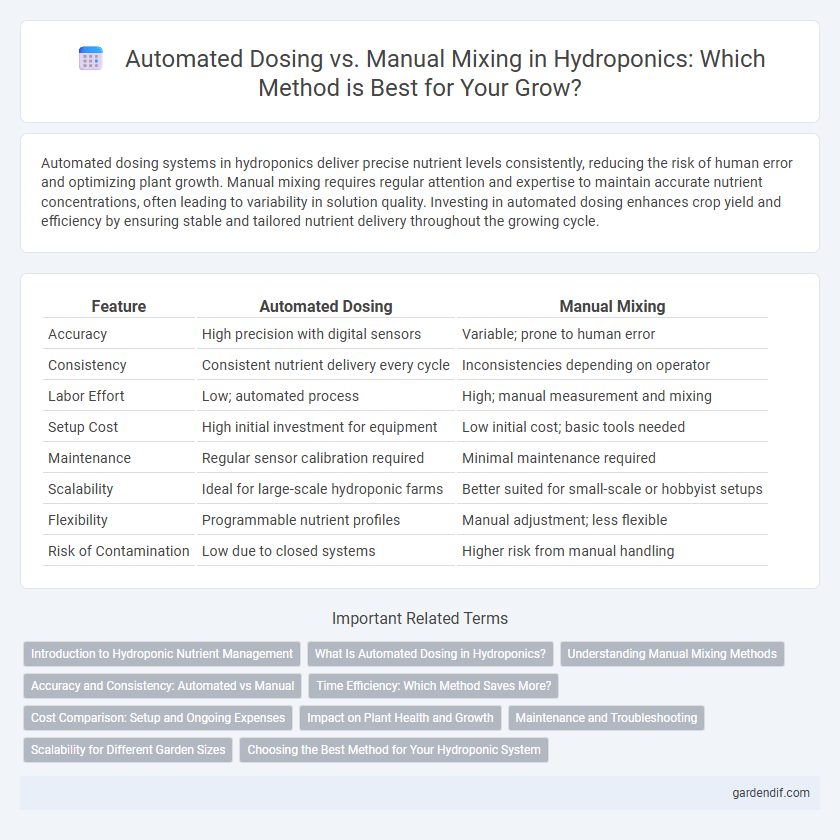

Table of Comparison

| Feature | Automated Dosing | Manual Mixing |

|---|---|---|

| Accuracy | High precision with digital sensors | Variable; prone to human error |

| Consistency | Consistent nutrient delivery every cycle | Inconsistencies depending on operator |

| Labor Effort | Low; automated process | High; manual measurement and mixing |

| Setup Cost | High initial investment for equipment | Low initial cost; basic tools needed |

| Maintenance | Regular sensor calibration required | Minimal maintenance required |

| Scalability | Ideal for large-scale hydroponic farms | Better suited for small-scale or hobbyist setups |

| Flexibility | Programmable nutrient profiles | Manual adjustment; less flexible |

| Risk of Contamination | Low due to closed systems | Higher risk from manual handling |

Introduction to Hydroponic Nutrient Management

Automated dosing technology in hydroponic nutrient management enhances precision by delivering exact concentrations of nutrients based on real-time sensor data, optimizing plant growth conditions and reducing nutrient waste. Manual mixing relies on human judgment and can lead to inconsistent nutrient concentrations, affecting crop yield and quality. Integrating automated dosing systems ensures consistent nutrient availability, improving overall system efficiency and plant health in hydroponic cultivation.

What Is Automated Dosing in Hydroponics?

Automated dosing in hydroponics refers to the use of advanced systems that precisely measure and deliver nutrient solutions to plants, ensuring consistent and optimal growth conditions. These systems employ sensors and controllers to adjust nutrient concentration, pH levels, and water flow based on real-time data, reducing human error and labor. Automated dosing enhances nutrient efficiency, promotes healthy root development, and maximizes crop yields compared to manual mixing methods.

Understanding Manual Mixing Methods

Manual mixing in hydroponic systems involves precisely measuring nutrients and dissolving them into water, requiring careful attention to concentration and pH levels to ensure optimal plant growth. Growers must regularly test nutrient solutions using tools like EC meters and pH meters to maintain balanced and consistent mixes. Unlike automated dosing, manual mixing demands hands-on expertise but allows for immediate adjustments tailored to specific crop needs.

Accuracy and Consistency: Automated vs Manual

Automated dosing systems in hydroponics ensure precise nutrient delivery by using sensors and programmable controls to maintain optimal concentrations, reducing human error and variability. Manual mixing methods often result in inconsistent nutrient levels due to measurement inaccuracies and variability in mixing time, impacting plant growth and yield. Consistent nutrient dosing through automation enhances crop health and maximizes efficiency compared to manual techniques.

Time Efficiency: Which Method Saves More?

Automated dosing systems significantly enhance time efficiency in hydroponic nutrient management by precisely delivering nutrients without constant monitoring, reducing labor hours compared to manual mixing. Manual mixing requires frequent measurement, adjustment, and stirring, consuming more time and increasing the potential for human error. Therefore, automated dosing saves more time and ensures consistent nutrient delivery for optimal plant growth.

Cost Comparison: Setup and Ongoing Expenses

Automated dosing systems for hydroponics require higher initial investment, typically ranging from $500 to $2,000, compared to manual mixing setups that cost under $100. Ongoing expenses for automated systems include maintenance, calibration, and software updates, which can add $100 to $300 annually, while manual mixing mainly incurs costs for labor and basic nutrient supplies. Over time, automated dosing reduces labor costs and nutrient wastage, potentially offsetting higher upfront expenses for larger or commercial hydroponic operations.

Impact on Plant Health and Growth

Automated dosing systems deliver precise nutrient concentrations consistently, reducing the risk of nutrient imbalances that can stunt plant growth or cause deficiencies. Manual mixing often leads to variability in nutrient solutions, which may stress plants and hinder optimal development. Consistent and accurate nutrient delivery from automated dosing enhances photosynthesis efficiency and promotes healthier, faster plant growth in hydroponic systems.

Maintenance and Troubleshooting

Automated dosing systems in hydroponics significantly reduce maintenance by minimizing human error and ensuring precise nutrient delivery, leading to consistent plant growth. Manual mixing requires frequent calibration and monitoring to avoid nutrient imbalances, increasing troubleshooting time and labor costs. Automated systems offer integrated diagnostics and alerts, simplifying troubleshooting and enhancing overall system reliability.

Scalability for Different Garden Sizes

Automated dosing systems enable precise nutrient delivery and consistent pH levels, making them ideal for scaling hydroponic gardens from small home setups to large commercial operations. Manual mixing requires more labor and increases the risk of human error, which can hinder scalability and nutrient consistency in larger or more complex systems. Investing in automation supports efficient resource management and optimal plant growth across diverse garden sizes.

Choosing the Best Method for Your Hydroponic System

Automated dosing systems provide precise nutrient delivery by using sensors and software to adjust concentrations in real-time, enhancing plant growth and reducing human error. Manual mixing requires regular monitoring and hands-on adjustments, which can lead to inconsistencies but offers greater control for small-scale or experimental setups. Selecting the best method depends on factors such as system size, budget, and desired nutrient precision, with automated dosing favored for commercial operations and manual mixing often preferred in hobbyist or research contexts.

Automated Dosing vs Manual Mixing Infographic

gardendif.com

gardendif.com