EC Calibration vs pH Calibration Illustration

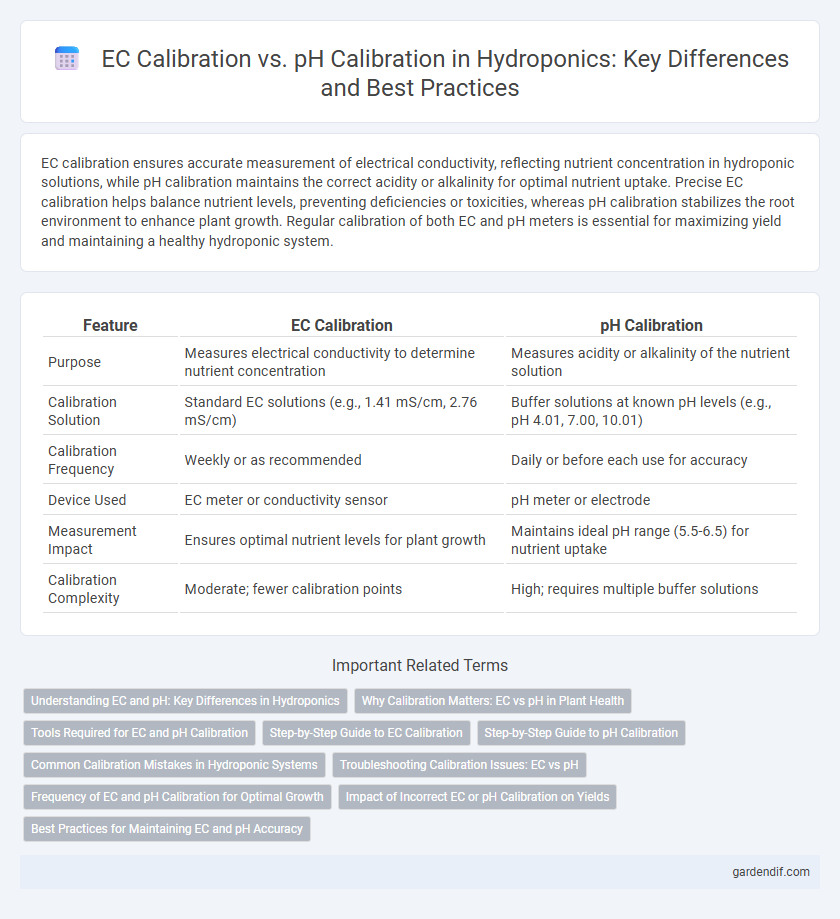

EC calibration ensures accurate measurement of electrical conductivity, reflecting nutrient concentration in hydroponic solutions, while pH calibration maintains the correct acidity or alkalinity for optimal nutrient uptake. Precise EC calibration helps balance nutrient levels, preventing deficiencies or toxicities, whereas pH calibration stabilizes the root environment to enhance plant growth. Regular calibration of both EC and pH meters is essential for maximizing yield and maintaining a healthy hydroponic system.

Table of Comparison

| Feature | EC Calibration | pH Calibration |

|---|---|---|

| Purpose | Measures electrical conductivity to determine nutrient concentration | Measures acidity or alkalinity of the nutrient solution |

| Calibration Solution | Standard EC solutions (e.g., 1.41 mS/cm, 2.76 mS/cm) | Buffer solutions at known pH levels (e.g., pH 4.01, 7.00, 10.01) |

| Calibration Frequency | Weekly or as recommended | Daily or before each use for accuracy |

| Device Used | EC meter or conductivity sensor | pH meter or electrode |

| Measurement Impact | Ensures optimal nutrient levels for plant growth | Maintains ideal pH range (5.5-6.5) for nutrient uptake |

| Calibration Complexity | Moderate; fewer calibration points | High; requires multiple buffer solutions |

Understanding EC and pH: Key Differences in Hydroponics

EC calibration measures the electrical conductivity of nutrient solutions, reflecting the concentration of dissolved salts essential for plant growth in hydroponics. pH calibration adjusts the hydrogen ion concentration to maintain an optimal acidic or alkaline environment, crucial for nutrient availability and uptake. Accurate calibration of both EC and pH sensors ensures balanced nutrient delivery and healthy crop development in hydroponic systems.

Why Calibration Matters: EC vs pH in Plant Health

Calibration of Electrical Conductivity (EC) and pH meters is crucial for maintaining optimal nutrient levels and acidity in hydroponic systems, directly influencing plant health and growth. Precise EC calibration ensures accurate measurement of nutrient concentration, preventing deficiencies or toxicities, while pH calibration maintains the correct nutrient availability by regulating hydrogen ion concentration. Consistent calibration prevents nutrient lockout, promotes efficient nutrient uptake, and supports vigorous plant development in hydroponic cultivation.

Tools Required for EC and pH Calibration

EC calibration requires a digital conductivity meter and standard calibration solutions with known electrical conductivity values, often ranging from 1413 uS/cm to 12880 uS/cm. pH calibration involves a pH meter and specific buffer solutions at stable pH values, commonly pH 4.00, 7.00, and 10.00, ensuring accurate sensor adjustments. Both calibration processes need clean containers and temperature compensation tools for precision in hydroponic nutrient management.

Step-by-Step Guide to EC Calibration

EC calibration involves adjusting the electrical conductivity meter to accurately measure nutrient solution concentration, essential for optimal hydroponic plant growth. Begin by preparing a standard EC calibration solution, typically 1413 uS/cm at 25degC, then immerse the EC meter probe into the solution and wait for the reading to stabilize. Finally, adjust the meter reading to match the known value of the calibration solution, ensuring precise nutrient delivery control in hydroponic systems.

Step-by-Step Guide to pH Calibration

To ensure optimal nutrient absorption in hydroponic systems, precise pH calibration is crucial and involves using standard buffer solutions, typically pH 4, 7, and 10, to adjust the pH meter accurately. Begin by rinsing the electrode with distilled water, then immerse it in the first buffer solution, allowing the meter to stabilize before calibrating to that pH level; repeat the process with the second and third buffers for a multi-point calibration. This step-by-step approach guarantees reliable pH measurements essential for maintaining the ideal growing environment, contrasting with EC calibration, which focuses on conductivity levels affecting nutrient strength.

Common Calibration Mistakes in Hydroponic Systems

Common calibration mistakes in hydroponic systems include neglecting to regularly calibrate EC and pH meters, leading to inaccurate nutrient and acidity readings that can stress plants. Using expired or contaminated calibration solutions compromises sensor accuracy, causing nutrient imbalances and poor plant growth. Failing to rinse probes between samples results in cross-contamination, distorting EC and pH measurements critical for maintaining optimal hydroponic conditions.

Troubleshooting Calibration Issues: EC vs pH

Troubleshooting calibration issues in hydroponic systems often requires understanding the distinct properties of EC and pH meters; EC calibration involves standard solutions with known electrical conductivity values, while pH calibration uses buffer solutions at specific pH levels. Common EC calibration problems include sensor fouling and temperature variations, which can lead to inaccurate readings, whereas pH calibration issues frequently stem from probe aging and contamination affecting electrode response. Regular maintenance, precise use of calibration standards, and temperature compensation are critical for ensuring accurate and reliable measurements in both EC and pH calibration processes.

Frequency of EC and pH Calibration for Optimal Growth

Frequent EC calibration every 7 to 14 days ensures accurate nutrient concentration measurements critical for plant nutrient uptake in hydroponic systems. pH calibration should occur weekly to maintain optimal acidity levels, as pH fluctuations directly affect nutrient availability and overall plant health. Regular calibration of both EC and pH meters maximizes crop yield by providing precise monitoring essential for balanced nutrient solutions.

Impact of Incorrect EC or pH Calibration on Yields

Incorrect EC calibration can cause nutrient imbalances that stunt plant growth and significantly reduce hydroponic yields by either causing nutrient deficiencies or toxicities. Poor pH calibration disrupts nutrient availability, leading to impaired nutrient uptake and resulting in lower crop quality and yield. Maintaining precise EC and pH calibration ensures optimal nutrient absorption and maximizes hydroponic crop productivity.

Best Practices for Maintaining EC and pH Accuracy

Maintaining accurate EC (Electrical Conductivity) and pH levels is critical for optimizing hydroponic nutrient solutions and ensuring plant health. Best practices for EC calibration include using fresh, standardized calibration solutions at the target temperature, regularly cleaning EC probes to prevent residue buildup, and performing frequent recalibrations to address sensor drift. For pH calibration, always calibrate with at least two standard buffer solutions (usually pH 4.01 and 7.00), store probes in appropriate storage solutions to preserve electrode lifespan, and rinse probes with deionized water before each measurement to maintain precision.

EC Calibration vs pH Calibration Infographic

gardendif.com

gardendif.com