Manual threshing vs Machine threshing Illustration

Manual threshing involves separating grains from stalks by hand, requiring significant labor and time, which can limit efficiency on larger farms. Machine threshing uses advanced equipment to rapidly and effectively separate grains, increasing productivity and reducing post-harvest losses. Transitioning to machine threshing enhances overall harvest quality while minimizing physical strain on workers.

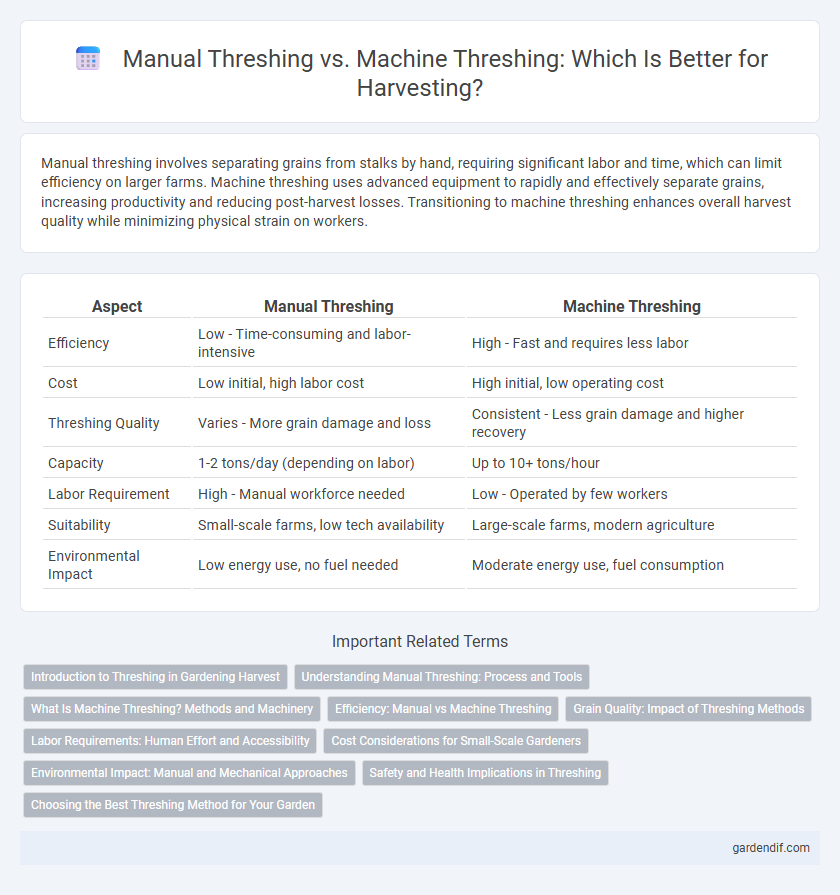

Table of Comparison

| Aspect | Manual Threshing | Machine Threshing |

|---|---|---|

| Efficiency | Low - Time-consuming and labor-intensive | High - Fast and requires less labor |

| Cost | Low initial, high labor cost | High initial, low operating cost |

| Threshing Quality | Varies - More grain damage and loss | Consistent - Less grain damage and higher recovery |

| Capacity | 1-2 tons/day (depending on labor) | Up to 10+ tons/hour |

| Labor Requirement | High - Manual workforce needed | Low - Operated by few workers |

| Suitability | Small-scale farms, low tech availability | Large-scale farms, modern agriculture |

| Environmental Impact | Low energy use, no fuel needed | Moderate energy use, fuel consumption |

Introduction to Threshing in Gardening Harvest

Threshing in gardening harvest is the process of separating grains or seeds from the harvested crop, crucial for preparing produce for consumption or storage. Manual threshing involves using simple tools like flails or beating crops against a hard surface, requiring significant labor and time, making it suitable for small-scale or subsistence farming. Machine threshing utilizes mechanized equipment such as threshers or combine harvesters to efficiently and quickly separate seeds, increasing productivity and reducing post-harvest losses in large-scale agricultural operations.

Understanding Manual Threshing: Process and Tools

Manual threshing involves separating grains from the harvested crop using traditional tools such as wooden flails or sticks, relying heavily on physical labor and skill. The process typically includes beating sheaves on a hard surface to detach the grains, followed by winnowing to remove chaff and impurities. While slower and labor-intensive, manual threshing offers cost-effective advantages for small-scale farmers with limited access to mechanized equipment.

What Is Machine Threshing? Methods and Machinery

Machine threshing involves the use of specialized equipment to separate grains from crop stalks efficiently and quickly. Common methods include drum threshers, rotary threshers, and combine harvesters, which integrate reaping, threshing, and winnowing in a single operation. These machines enhance productivity by reducing labor intensity and minimizing grain losses compared to manual threshing methods.

Efficiency: Manual vs Machine Threshing

Manual threshing requires significantly more time and labor, processing only small batches of grain per hour. Machine threshing increases efficiency by rapidly separating grain from the stalks, handling large volumes and reducing post-harvest losses. The adoption of mechanized threshers leads to higher productivity, lower labor costs, and faster turnaround during the critical harvest period.

Grain Quality: Impact of Threshing Methods

Manual threshing preserves grain quality by minimizing physical damage and reducing the risk of contamination, essential for high-value crops like wheat and rice. Machine threshing increases efficiency but may cause higher kernel breakage and mixed impurities, affecting overall grain purity and market value. Selecting the appropriate threshing method depends on crop type, desired grain quality, and available resources to optimize harvest outcomes.

Labor Requirements: Human Effort and Accessibility

Manual threshing demands significant human effort and is labor-intensive, often requiring multiple workers over extended periods to separate grains from stalks. Machine threshing reduces labor requirements drastically by automating the process, increasing efficiency and accessibility for large-scale farming operations. In regions with limited access to mechanized equipment, manual threshing remains prevalent despite its higher physical demands.

Cost Considerations for Small-Scale Gardeners

Manual threshing remains a cost-effective option for small-scale gardeners due to minimal initial investment and low maintenance expenses compared to machinery. Machine threshing, while faster and more efficient, involves higher upfront costs including equipment purchase, fuel, and repairs, which may not be justifiable for limited harvest volumes. Evaluating labor availability and long-term usage frequency is essential to determine the most economical threshing method for small garden operations.

Environmental Impact: Manual and Mechanical Approaches

Manual threshing produces minimal carbon emissions and preserves soil structure by causing less compaction, making it more environmentally sustainable for small-scale farming. Machine threshing increases efficiency and reduces labor but generates higher greenhouse gas emissions due to fossil fuel use and contributes to soil degradation through repeated heavy machinery traffic. Choosing between manual and mechanical threshing involves balancing ecological footprints with productivity demands, highlighting the need for sustainable farming innovations.

Safety and Health Implications in Threshing

Manual threshing exposes workers to repetitive strain injuries, respiratory issues from dust inhalation, and potential cuts from sharp tools, posing significant safety and health risks. Machine threshing reduces physical labor and exposure to dust, but introduces hazards such as noise-induced hearing loss, mechanical accidents, and the need for proper operator training to prevent injuries. Implementing safety measures like protective gear, regular maintenance, and health monitoring is crucial to minimize risks in both manual and machine threshing processes.

Choosing the Best Threshing Method for Your Garden

Manual threshing offers precise control and minimal crop damage, ideal for small gardens and delicate grains. Machine threshing increases efficiency and reduces labor time, suitable for larger-scale harvests with tougher crops. Assess garden size, crop type, and budget to choose the optimal threshing method that maximizes yield and maintains grain quality.

Manual threshing vs Machine threshing Infographic

gardendif.com

gardendif.com