Manual Pick vs Machine Pick Illustration

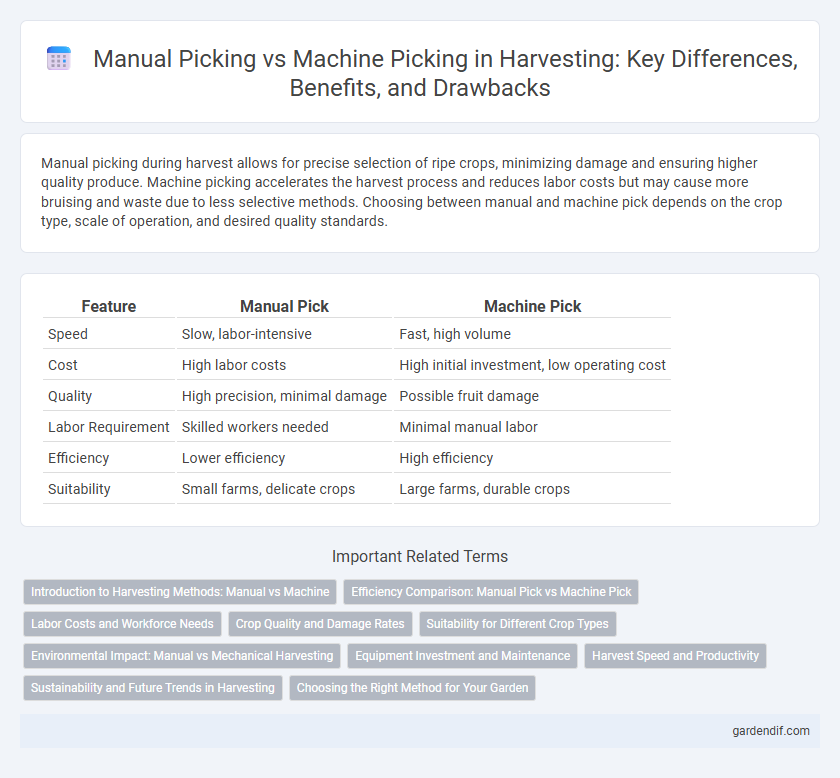

Manual picking during harvest allows for precise selection of ripe crops, minimizing damage and ensuring higher quality produce. Machine picking accelerates the harvest process and reduces labor costs but may cause more bruising and waste due to less selective methods. Choosing between manual and machine pick depends on the crop type, scale of operation, and desired quality standards.

Table of Comparison

| Feature | Manual Pick | Machine Pick |

|---|---|---|

| Speed | Slow, labor-intensive | Fast, high volume |

| Cost | High labor costs | High initial investment, low operating cost |

| Quality | High precision, minimal damage | Possible fruit damage |

| Labor Requirement | Skilled workers needed | Minimal manual labor |

| Efficiency | Lower efficiency | High efficiency |

| Suitability | Small farms, delicate crops | Large farms, durable crops |

Introduction to Harvesting Methods: Manual vs Machine

Manual harvest involves hand-picking crops, allowing selective harvesting and minimal damage to delicate produce, ideal for fruits and vegetables requiring careful handling. Machine harvest uses mechanical equipment to rapidly gather large quantities, improving efficiency and reducing labor costs but potentially causing more crop bruising and requiring uniform field conditions. Choosing between manual and machine harvesting depends on crop type, scale of operation, and desired quality standards.

Efficiency Comparison: Manual Pick vs Machine Pick

Manual picking offers precise selection and minimal crop damage, making it ideal for delicate harvests, but it generally requires more labor hours and slower throughput. Machine picking significantly increases harvesting speed and efficiency, covering larger areas in less time, although it may cause higher crop damage and less selectivity. Efficiency comparison reveals that while manual picking excels in quality control, machine picking dominates in volume and time savings, influencing operational scale decisions.

Labor Costs and Workforce Needs

Manual picking requires a larger workforce and significantly increases labor costs due to the intensive handpicking process. Machine picking reduces the need for seasonal labor and lowers labor expenses but may compromise selectivity and fruit quality. Balancing labor costs and workforce availability is essential for optimizing harvest efficiency and profitability.

Crop Quality and Damage Rates

Manual picking preserves crop quality by allowing selective harvesting and minimizing bruising, resulting in fresher produce with fewer defects. Machine picking increases harvest speed but often causes higher damage rates due to mechanical impact, leading to reduced shelf life and lower market value. Balancing efficiency with crop quality is crucial when choosing between manual and machine harvesting methods.

Suitability for Different Crop Types

Manual picking allows precise selection and minimal damage, making it ideal for delicate crops like berries, grapes, and specialty vegetables requiring gentle handling. Machine picking suits large-scale harvests of robust crops such as grains, apples, and citrus fruits, where speed and volume outweigh the risk of minor bruising. Crop type, terrain, and labor availability significantly influence the choice between manual and mechanical harvesting methods.

Environmental Impact: Manual vs Mechanical Harvesting

Manual harvesting minimizes soil compaction and preserves ecosystem biodiversity by reducing heavy machinery use, which otherwise leads to increased fuel consumption and greenhouse gas emissions. Mechanical harvesting accelerates the gathering process but contributes to higher carbon footprints, soil degradation, and potential damage to surrounding flora and fauna. Sustainable agricultural practices favor manual pick methods to enhance environmental health, despite higher labor demands.

Equipment Investment and Maintenance

Manual harvest requires minimal initial equipment investment but demands higher labor costs and ongoing workforce management. Machine harvesting involves significant upfront investment in specialized equipment such as combines and mechanical pickers, with regular maintenance costs including repairs, parts replacement, and calibration. The long-term efficiency of machine picking often offsets the high capital expenditure through faster harvest times and reduced labor dependency.

Harvest Speed and Productivity

Manual picking in harvesting offers precision and minimal crop damage but generally results in slower harvest speed and lower productivity compared to machine picking. Machine picking significantly increases harvest speed by covering larger areas quickly, leading to higher overall productivity and cost-efficiency. Advances in automated harvesting technology continue to enhance machine picking accuracy, narrowing the quality gap with manual labor while maximizing output.

Sustainability and Future Trends in Harvesting

Manual picking in harvest preserves crop integrity and reduces mechanical damage, supporting sustainable agricultural practices by minimizing energy consumption and soil compaction. Machine picking increases efficiency and scalability but can contribute to higher carbon emissions and potential crop waste if not optimized. Future trends emphasize hybrid systems integrating AI-guided robotics to balance sustainability with productivity in harvesting operations.

Choosing the Right Method for Your Garden

Manual picking allows precise selection of ripe fruits, reducing damage and preserving plant health, ideal for small gardens or delicate crops like berries and tomatoes. Machine picking significantly speeds up the harvest process, making it suitable for large-scale operations with sturdy crops such as apples or potatoes. Evaluate crop type, garden size, and labor availability to choose the most efficient harvest method, ensuring optimal yield and quality.

Manual Pick vs Machine Pick Infographic

gardendif.com

gardendif.com