Gentle picking vs Rapid picking Illustration

Gentle picking preserves the quality and freshness of crops by minimizing bruising and damage, ensuring a longer shelf life and better taste. Rapid picking increases efficiency and allows for large-scale harvests but may compromise the integrity of delicate fruits and vegetables. Balancing speed with care is crucial for maximizing yield while maintaining produce quality.

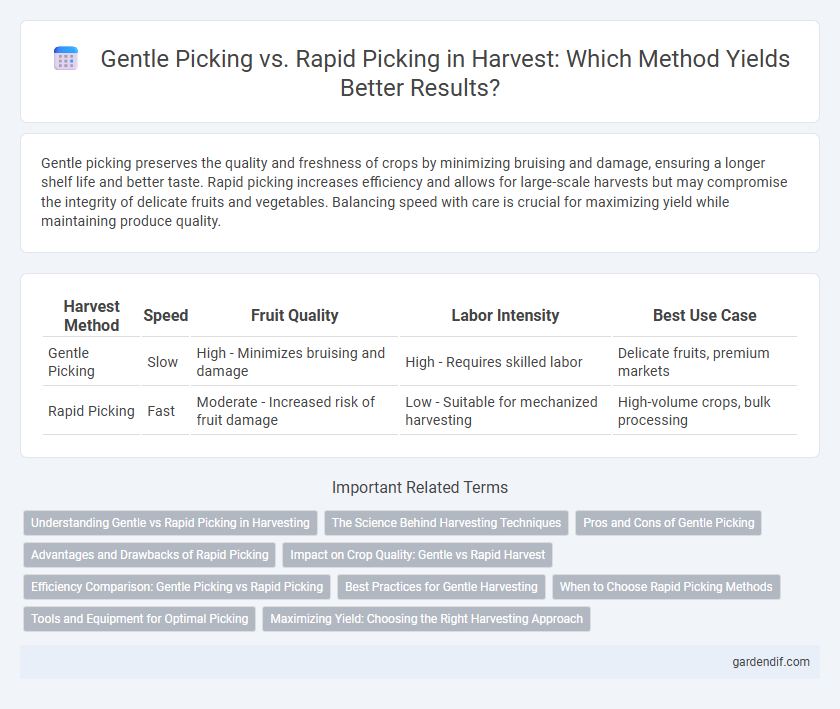

Table of Comparison

| Harvest Method | Speed | Fruit Quality | Labor Intensity | Best Use Case |

|---|---|---|---|---|

| Gentle Picking | Slow | High - Minimizes bruising and damage | High - Requires skilled labor | Delicate fruits, premium markets |

| Rapid Picking | Fast | Moderate - Increased risk of fruit damage | Low - Suitable for mechanized harvesting | High-volume crops, bulk processing |

Understanding Gentle vs Rapid Picking in Harvesting

Gentle picking in harvesting prioritizes preserving fruit integrity and minimizing damage, which is crucial for delicate crops like berries and grapes. Rapid picking maximizes efficiency and speed, often used for hardier fruits or large-scale operations where volume is prioritized over individual fruit quality. Understanding the trade-offs between gentle and rapid picking methods helps optimize harvest outcomes based on crop type, market demands, and post-harvest handling requirements.

The Science Behind Harvesting Techniques

Gentle picking minimizes mechanical damage to crops by applying precise pressure and avoiding bruising, which preserves nutritional quality and extends shelf life. Rapid picking increases harvesting speed but often causes cellular rupture and accelerates spoilage due to careless handling. Scientific research shows that balancing picking speed with gentle techniques enhances overall crop quality and post-harvest longevity.

Pros and Cons of Gentle Picking

Gentle picking minimizes fruit bruising and damage, preserving quality and extending shelf life, making it ideal for delicate crops like berries and peaches. This method requires more labor and time, increasing harvesting costs and potentially reducing overall efficiency. The careful approach enhances market value but may limit the volume of produce collected compared to rapid picking techniques.

Advantages and Drawbacks of Rapid Picking

Rapid picking significantly increases harvest efficiency by enabling faster fruit collection and reducing labor costs. However, it often leads to higher fruit damage and reduced quality due to less careful handling compared to gentle picking methods. This trade-off between speed and product integrity makes rapid picking suitable for crops where volume outweighs premium quality demands.

Impact on Crop Quality: Gentle vs Rapid Harvest

Gentle picking preserves the integrity of delicate crops by minimizing bruising, moisture loss, and cell damage, resulting in higher market quality and longer shelf life. Rapid picking increases harvest speed but often causes mechanical stress, leading to reduced crop appearance, accelerated spoilage, and diminished nutritional value. Optimal harvest strategies balance efficiency with techniques that protect crop quality to maximize yield value.

Efficiency Comparison: Gentle Picking vs Rapid Picking

Gentle picking minimizes fruit damage and preserves quality, resulting in higher market value despite slower throughput. Rapid picking increases harvest speed and labor productivity but risks bruising and reduced shelf life due to mechanical stress. Balancing gentle methods with optimized labor allocation enhances overall harvest efficiency and product profitability.

Best Practices for Gentle Harvesting

Gentle picking techniques emphasize careful handling to minimize damage to delicate fruits, preserving quality and extending shelf life. Best practices include using soft gloves, hand-picking instead of mechanical methods, and immediate placement into padded containers to prevent bruising. Harvesting during cooler parts of the day further reduces stress on produce, ensuring optimal freshness and market value.

When to Choose Rapid Picking Methods

Rapid picking methods are ideal for crops with high perishability or when harvesting large volumes within tight timeframes, such as berries or leafy greens. This approach minimizes the risk of spoilage and ensures quicker delivery to markets or processing facilities. Selecting rapid picking optimizes operational efficiency when labor resources are limited and speed is essential.

Tools and Equipment for Optimal Picking

Gentle picking requires specialized tools such as padded gloves, soft mesh baskets, and precision shears designed to minimize bruising and preserve fruit quality. Rapid picking emphasizes ergonomic harvesters, large-capacity bins, and mechanical aids like conveyor belts to maximize speed while maintaining efficient fruit collection. Selecting appropriate equipment balances harvest speed with product integrity, ensuring optimal yield and quality.

Maximizing Yield: Choosing the Right Harvesting Approach

Gentle picking minimizes damage to delicate crops like berries and grapes, preserving quality and reducing post-harvest losses, which maximizes overall yield value. Rapid picking suits hardier produce such as apples and citrus, enabling quicker harvest of large volumes during peak ripeness to prevent spoilage. Selecting the appropriate harvesting method based on crop type and market demands enhances efficiency, optimizes yield, and maintains product integrity.

Gentle picking vs Rapid picking Infographic

gardendif.com

gardendif.com