Batch composting vs Continuous composting Illustration

Batch composting involves processing organic waste in discrete, manageable piles or containers, allowing for precise control over temperature and aeration to optimize decomposition. Continuous composting operates by continuously adding fresh material while removing mature compost, supporting ongoing microbial activity and efficient space utilization. Choosing between batch and continuous composting depends on factors like available space, desired processing time, and the scale of organic waste management.

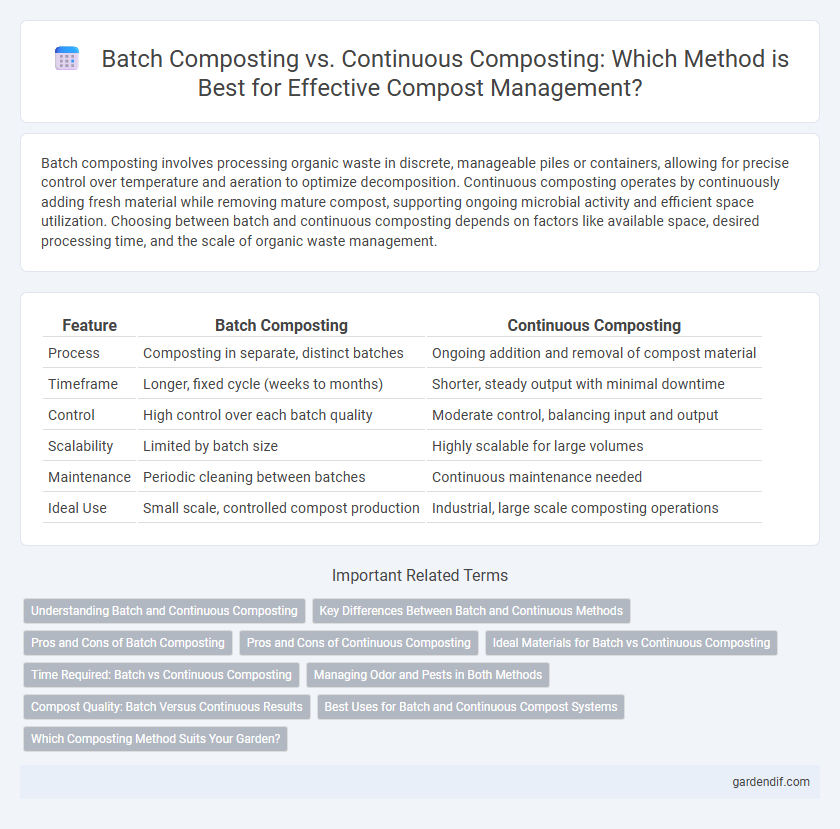

Table of Comparison

| Feature | Batch Composting | Continuous Composting |

|---|---|---|

| Process | Composting in separate, distinct batches | Ongoing addition and removal of compost material |

| Timeframe | Longer, fixed cycle (weeks to months) | Shorter, steady output with minimal downtime |

| Control | High control over each batch quality | Moderate control, balancing input and output |

| Scalability | Limited by batch size | Highly scalable for large volumes |

| Maintenance | Periodic cleaning between batches | Continuous maintenance needed |

| Ideal Use | Small scale, controlled compost production | Industrial, large scale composting operations |

Understanding Batch and Continuous Composting

Batch composting involves processing organic waste in discrete, manageable piles or bins, allowing for better control over temperature and aeration to optimize microbial activity. Continuous composting maintains a steady input of organic material, promoting ongoing decomposition but requiring more sophisticated systems to balance moisture, oxygen, and nutrient levels. Understanding the differences in process dynamics and management requirements helps select the appropriate method for specific composting goals and waste volumes.

Key Differences Between Batch and Continuous Methods

Batch composting involves processing organic material in discrete, separate piles or bins until fully decomposed, allowing for easier monitoring of temperature and moisture levels. Continuous composting operates with a steady input and output of materials, enabling faster turnover and consistent production but requiring more advanced management to control odors and microbial activity. Key differences include the timeframe for decomposition, control over environmental conditions, and scalability for commercial versus small-scale use.

Pros and Cons of Batch Composting

Batch composting offers advantages such as simplicity in operation and easier control over temperature and moisture levels, promoting effective decomposition. However, it requires more space and labor due to periodic turning and handling, resulting in downtime between batches that can slow overall compost production. The closed nature of batch systems limits continuous input, making it less suitable for high-volume or constant organic waste processing compared to continuous composting methods.

Pros and Cons of Continuous Composting

Continuous composting offers the advantage of steady waste processing, reducing storage space and minimizing odor issues by maintaining active microbial conditions. This method allows for consistent nutrient-rich compost output, ideal for large-scale operations with ongoing organic waste streams. However, continuous composting requires careful monitoring of temperature, moisture, and aeration to prevent imbalances, and the complexity of managing multiple composting stages can increase operational costs.

Ideal Materials for Batch vs Continuous Composting

Batch composting is ideal for materials like yard waste, kitchen scraps, and agricultural residues that can be processed in large, uniform quantities over a set period. Continuous composting suits diverse organic inputs such as food waste, manure, and paper products, which are added incrementally to maintain an ongoing decomposition process. Selecting the right material based on moisture content, carbon-to-nitrogen ratio, and particle size enhances efficiency in both batch and continuous composting systems.

Time Required: Batch vs Continuous Composting

Batch composting typically requires a fixed processing time, often ranging from several weeks to a few months, as the compost is turned and managed in discrete cycles until maturity. Continuous composting allows for ongoing input and extraction, producing compost more steadily without the need for complete system shutdowns, which can reduce overall processing time per batch. The time efficiency of continuous composting is often higher due to its ability to maintain optimal conditions year-round, accelerating organic matter decomposition compared to the intermittent nature of batch composting.

Managing Odor and Pests in Both Methods

Batch composting minimizes odor and pest issues by isolating materials in contained, sealed batches that decompose fully before turning, reducing exposure to air and pests. Continuous composting requires regular turning and aeration, which can increase odor and risk of pest attraction if not managed with proper carbon-to-nitrogen ratios and moisture control. Effective management in both methods involves balancing moisture, temperature, and oxygen levels to promote aerobic decomposition and minimize anaerobic odors and pest infestations.

Compost Quality: Batch Versus Continuous Results

Batch composting typically produces higher-quality compost due to controlled conditions and consistent microbial activity, leading to more thorough organic matter breakdown. Continuous composting may result in variable compost quality, as ongoing addition of fresh material disrupts microbial stability and prolongs maturation. Studies show batch systems often yield nutrient-rich, pathogen-free compost with better structure and moisture balance compared to continuous methods.

Best Uses for Batch and Continuous Compost Systems

Batch composting is ideal for producing high-quality compost in smaller quantities, making it suitable for garden enthusiasts and small-scale farmers who seek precise control over the decomposition process. Continuous composting systems work best for large-scale operations such as municipal waste management and commercial farms, where a steady supply of compost is needed and the process is streamlined for efficiency. Both systems optimize organic waste recycling but cater to different volume demands and operational priorities.

Which Composting Method Suits Your Garden?

Batch composting suits gardens with space for large, periodic compost piles and gardeners who prefer processing organic waste in distinct, manageable cycles. Continuous composting benefits gardens needing steady, ongoing compost production, allowing regular addition of materials without interruption. Choosing the right method depends on garden size, waste volume, and compost usage frequency.

Batch composting vs Continuous composting Infographic

gardendif.com

gardendif.com