Windrow Composting vs In-vessel Composting Illustration

Windrow composting involves piling organic waste into long rows that are periodically turned to enhance aeration and microbial activity, making it suitable for large-scale outdoor operations with abundant space. In-vessel composting confines organic material within a controlled, enclosed environment, allowing precise regulation of temperature, moisture, and airflow, which accelerates decomposition and reduces odor emissions. Both methods effectively recycle organic waste but differ in operational complexity, space requirements, and control over composting conditions.

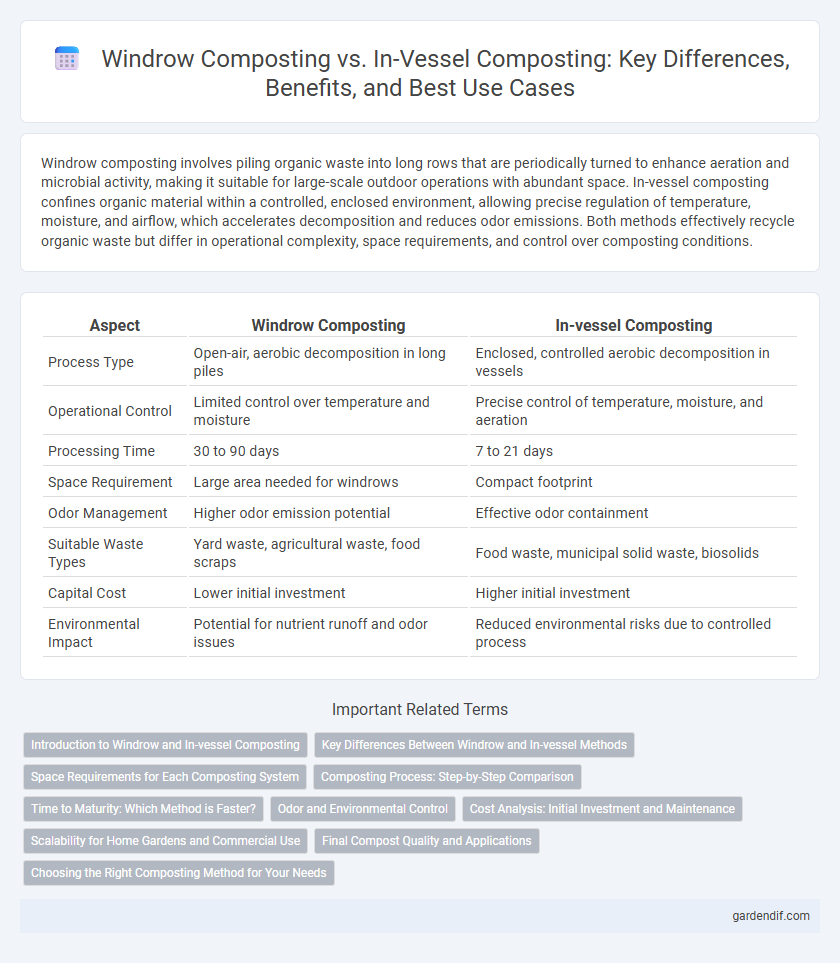

Table of Comparison

| Aspect | Windrow Composting | In-vessel Composting |

|---|---|---|

| Process Type | Open-air, aerobic decomposition in long piles | Enclosed, controlled aerobic decomposition in vessels |

| Operational Control | Limited control over temperature and moisture | Precise control of temperature, moisture, and aeration |

| Processing Time | 30 to 90 days | 7 to 21 days |

| Space Requirement | Large area needed for windrows | Compact footprint |

| Odor Management | Higher odor emission potential | Effective odor containment |

| Suitable Waste Types | Yard waste, agricultural waste, food scraps | Food waste, municipal solid waste, biosolids |

| Capital Cost | Lower initial investment | Higher initial investment |

| Environmental Impact | Potential for nutrient runoff and odor issues | Reduced environmental risks due to controlled process |

Introduction to Windrow and In-vessel Composting

Windrow composting involves the decomposition of organic materials arranged in long, open-air piles, relying on natural aeration and periodic turning to optimize microbial activity. In-vessel composting confines organic waste within a controlled, enclosed environment, allowing precise regulation of temperature, moisture, and aeration to accelerate decomposition. Both methods efficiently recycle organic waste but differ in space requirements, processing time, and environmental control capabilities.

Key Differences Between Windrow and In-vessel Methods

Windrow composting involves placing organic waste in long, open-air piles that rely on natural aeration and periodic turning to facilitate decomposition, making it suitable for large-scale, outdoor operations. In-vessel composting confines organic material within a controlled, enclosed environment, allowing precise regulation of temperature, moisture, and airflow, which accelerates the composting process and minimizes odors. Key differences include the scale of operation, environmental control, decomposition speed, and suitability for urban versus industrial settings.

Space Requirements for Each Composting System

Windrow composting requires significantly more space, typically needing open land areas of several thousand square feet to accommodate long, windrowed piles that facilitate aeration through turning. In-vessel composting is designed for compact, enclosed systems, allowing efficient organic waste processing in controlled environments often fitting within building footprints or small plots, occupying as little as a few hundred square feet. This spatial efficiency makes in-vessel composting ideal for urban or space-constrained locations, while windrow systems are better suited for rural settings with ample land availability.

Composting Process: Step-by-Step Comparison

Windrow composting involves piling organic waste into long rows, allowing natural aeration and microbial activity to decompose materials over several weeks with periodic turning for oxygen supply. In-vessel composting confines materials within a closed container, managing temperature, moisture, and aeration through controlled mechanical systems, enabling faster and more consistent decomposition within days to weeks. Both methods optimize microbial breakdown but differ in space requirements, process control, and speed of compost maturation.

Time to Maturity: Which Method is Faster?

Windrow composting typically requires 45 to 60 days to reach maturity, whereas in-vessel composting accelerates the process to as little as 14 to 21 days due to controlled temperature, moisture, and aeration. The enclosed environment of in-vessel systems optimizes microbial activity, significantly reducing decomposition time compared to the open-air method of windrow piles. Faster maturation in in-vessel composting enables quicker turnaround for organic waste recycling and nutrient-rich soil amendment production.

Odor and Environmental Control

Windrow composting can generate stronger odors due to open-air exposure, increasing the risk of odor nuisances and attracting pests, while in-vessel composting offers superior environmental control by containing odors within a sealed system. In-vessel composting facilitates precise regulation of temperature, moisture, and airflow, significantly reducing greenhouse gas emissions and leachate compared to windrow methods. This enhanced containment and control make in-vessel composting more effective for odor mitigation and minimizing environmental impact in urban or sensitive locations.

Cost Analysis: Initial Investment and Maintenance

Windrow composting requires a lower initial investment, typically involving land, aeration equipment, and machinery, with annual maintenance costs centered around labor and equipment repairs. In-vessel composting demands a high upfront capital expenditure for specialized enclosed systems and climate control technology, resulting in elevated maintenance costs tied to mechanical components and energy consumption. Cost efficiency of windrow methods is favored for large-scale, low-tech operations, while in-vessel systems suit urban or regulated environments despite higher financial commitments.

Scalability for Home Gardens and Commercial Use

Windrow composting offers scalability for large-scale commercial use due to its ability to process bulky organic waste in open-air piles, making it less suitable for small home gardens where space is limited. In-vessel composting provides a controlled environment that accelerates decomposition and is ideal for scalable applications, from compact home garden units to industrial facilities. Commercial operations benefit from in-vessel systems' efficiency and reduced odor, while home gardeners advantage from smaller, manageable in-vessel composters.

Final Compost Quality and Applications

Windrow composting typically produces compost with coarser texture and variable nutrient content, making it ideal for large-scale landscaping, agriculture, and soil amendment applications. In-vessel composting offers more controlled environmental conditions, resulting in consistently higher-quality compost with finer texture and enhanced pathogen reduction, suitable for horticulture, organic farming, and urban agriculture. Final compost quality from in-vessel systems often meets stricter regulatory standards, supporting its use in sensitive environments and commercial production.

Choosing the Right Composting Method for Your Needs

Windrow composting offers a cost-effective solution for processing large volumes of organic waste outdoors, ideal for agricultural or municipal settings with ample space. In-vessel composting provides a controlled environment that accelerates decomposition, reduces odors, and is suitable for urban or limited space applications requiring faster turnaround. Choosing the right method depends on factors like waste volume, site constraints, timeline, and odor management needs.

Windrow Composting vs In-vessel Composting Infographic

gardendif.com

gardendif.com