Mechanical weeding vs Thermal weeding Illustration

Mechanical weeding uses physical tools or machinery to remove weeds, offering precise control and minimal soil disturbance, making it ideal for sustainable agriculture. Thermal weeding applies heat through methods like flame or steam to destroy weed tissues, providing a chemical-free alternative that can be effective for organic farming. Both methods reduce reliance on herbicides but differ in energy use and impact on soil health, making the choice dependent on crop type and environmental goals.

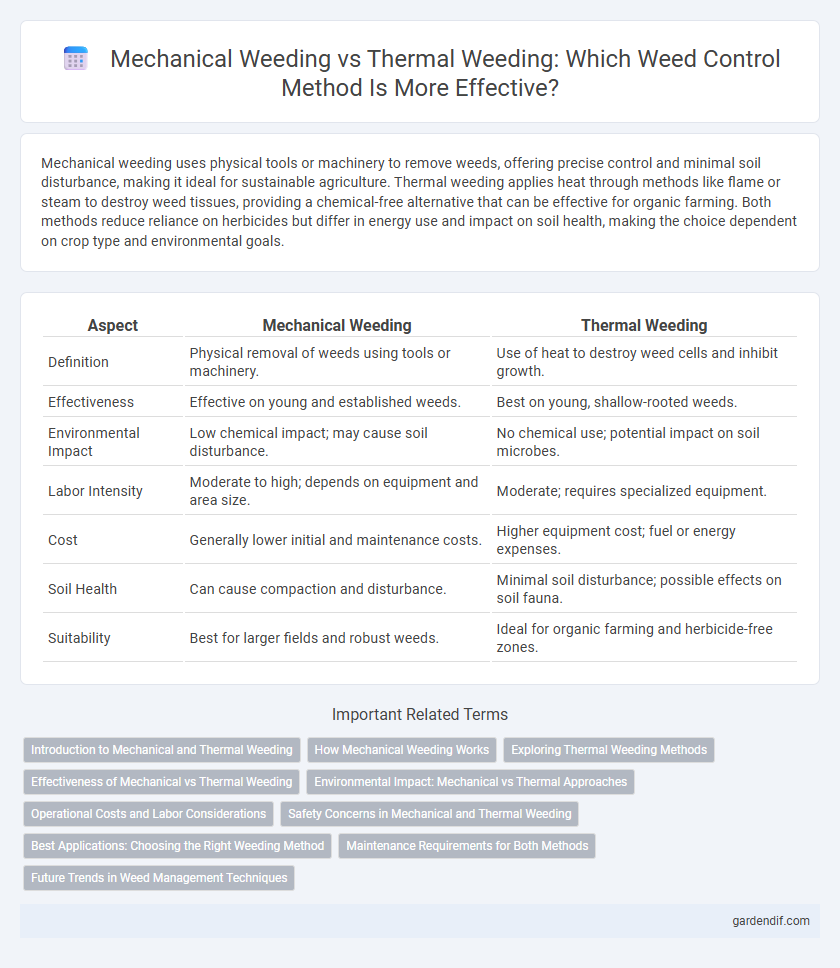

Table of Comparison

| Aspect | Mechanical Weeding | Thermal Weeding |

|---|---|---|

| Definition | Physical removal of weeds using tools or machinery. | Use of heat to destroy weed cells and inhibit growth. |

| Effectiveness | Effective on young and established weeds. | Best on young, shallow-rooted weeds. |

| Environmental Impact | Low chemical impact; may cause soil disturbance. | No chemical use; potential impact on soil microbes. |

| Labor Intensity | Moderate to high; depends on equipment and area size. | Moderate; requires specialized equipment. |

| Cost | Generally lower initial and maintenance costs. | Higher equipment cost; fuel or energy expenses. |

| Soil Health | Can cause compaction and disturbance. | Minimal soil disturbance; possible effects on soil fauna. |

| Suitability | Best for larger fields and robust weeds. | Ideal for organic farming and herbicide-free zones. |

Introduction to Mechanical and Thermal Weeding

Mechanical weeding involves physically removing weeds using tools such as hoes, cultivators, or specialized machinery, which reduces weed competition without chemicals. Thermal weeding utilizes heat sources like propane flamers or infrared radiation to destroy weed tissues, offering a non-chemical alternative that minimizes soil disturbance. Both methods contribute to sustainable weed management by targeting weeds through distinct physical mechanisms.

How Mechanical Weeding Works

Mechanical weeding employs tools such as hoes, cultivators, or specialized machinery to physically uproot or disturb weeds by cutting or uprooting them from the soil. This method targets weed roots and stem bases, disrupting growth and preventing nutrient uptake, which inhibits weed development without chemical use. Precision in depth and timing is crucial to maximize efficacy and minimize crop damage, making mechanical weeding a sustainable option for organic and conventional farming systems.

Exploring Thermal Weeding Methods

Thermal weeding methods utilize heat sources such as infrared radiation, flame, or steam to disrupt plant cell structure, making them effective for controlling weeds without chemicals. Infrared weeding targets the weed's foliage, causing cellular damage and plant death while minimizing soil disturbance. This approach is especially beneficial in organic farming and sustainable agriculture, offering precise weed control with reduced environmental impact.

Effectiveness of Mechanical vs Thermal Weeding

Mechanical weeding effectively removes weeds by physically uprooting or cutting them, delivering immediate and lasting control especially in row crops and large fields. Thermal weeding uses heat to destroy weed cells, offering precise control for young weed seedlings but often requiring multiple treatments for tougher or established weeds. Effectiveness varies with weed species, growth stage, and environmental conditions, with mechanical methods favoring durability and thermal methods excelling in eco-friendly, non-chemical applications.

Environmental Impact: Mechanical vs Thermal Approaches

Mechanical weeding reduces chemical runoff and soil disturbance by physically removing weeds, promoting healthier soil ecosystems and enhancing biodiversity. Thermal weeding uses heat to destroy weeds, which minimizes soil compaction but can release greenhouse gases depending on the energy source. Comparing environmental impact, mechanical weeding generally supports long-term soil health, while thermal weeding offers low chemical use but requires careful energy management to reduce carbon footprint.

Operational Costs and Labor Considerations

Mechanical weeding typically incurs higher operational costs due to machinery maintenance, fuel consumption, and the need for specialized operators, whereas thermal weeding requires significant energy input but reduces labor intensity by targeting weeds rapidly with heat. Labor considerations favor thermal weeding in large-scale applications as it demands fewer personnel and less manual intervention, while mechanical weeding often involves continuous monitoring and manual adjustments. Choosing between these methods depends on balancing equipment investment, energy costs, and available labor resources within the agricultural operation.

Safety Concerns in Mechanical and Thermal Weeding

Mechanical weeding poses safety concerns primarily due to the risk of physical injuries from sharp tools and machinery, requiring protective gear and proper training for operators. Thermal weeding, which uses heat sources like flame or hot water, raises concerns about burns, fire hazards, and respiratory risks from smoke or steam, demanding careful handling and appropriate safety measures. Both methods necessitate strict adherence to safety protocols to minimize accidents and health risks during weed management.

Best Applications: Choosing the Right Weeding Method

Mechanical weeding excels in large-scale farms and row crops where soil disturbance fosters weed control and enhances aeration. Thermal weeding suits organic gardens and sensitive horticultural crops, effectively targeting weed seedlings without soil disruption or chemical residues. Selecting the method depends on crop sensitivity, field size, and the desired level of soil impact for optimal weed management.

Maintenance Requirements for Both Methods

Mechanical weeding requires regular maintenance such as blade sharpening, engine tuning, and component lubrication to ensure effective operation and prevent breakdowns. Thermal weeding systems demand upkeep of burners, fuel lines, and ignition mechanisms, alongside periodic inspection for clogs or leaks to maintain consistent heat delivery. Both methods benefit from routine cleaning and safety checks, but mechanical equipment typically involves more frequent mechanical adjustments while thermal systems focus on fuel and combustion efficiency.

Future Trends in Weed Management Techniques

Mechanical weeding techniques are evolving with advancements in robotics and AI-driven precision tools that reduce crop damage and enhance efficiency. Thermal weeding, utilizing infrared and flame technologies, is gaining traction due to its chemical-free approach and suitability for organic farming systems. Future trends indicate a hybrid integration of both methods, leveraging technology for sustainable, eco-friendly weed control that minimizes environmental impact and supports crop health.

Mechanical weeding vs Thermal weeding Infographic

gardendif.com

gardendif.com