Batch processing vs continuous harvesting Illustration

Batch processing in harvesting involves collecting crops in distinct, separate groups, allowing for thorough quality checks and targeted processing but potentially causing delays between batches. Continuous harvesting operates by gathering crops non-stop, enhancing efficiency and throughput, which is ideal for high-volume operations but may risk inconsistencies in crop quality. Choosing between batch processing and continuous harvesting depends on the balance between speed, quality control, and operational scale required.

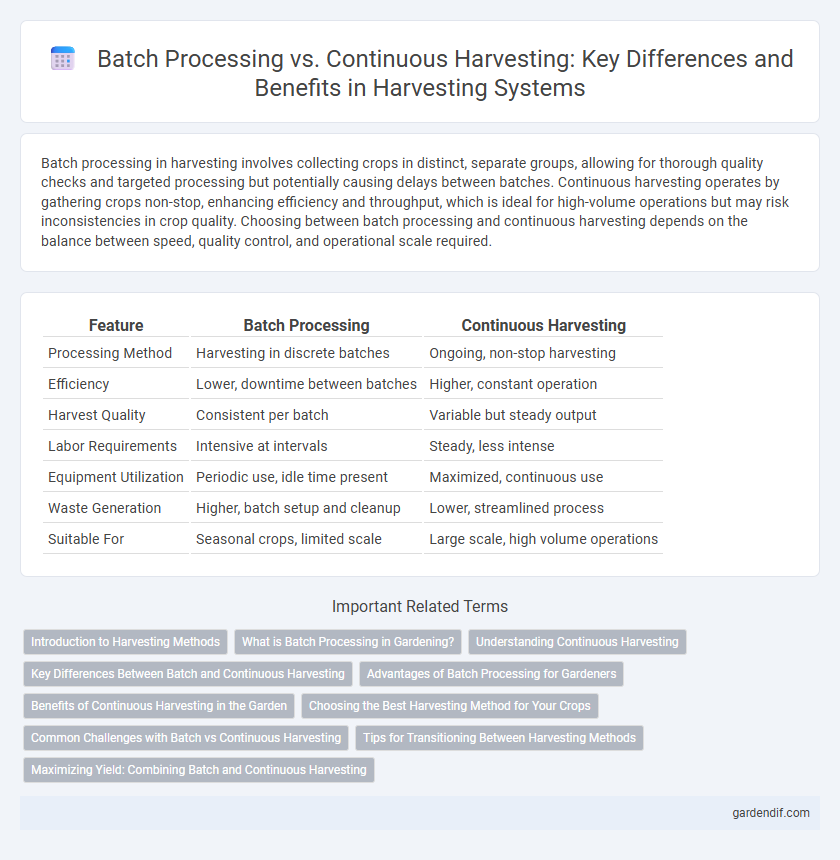

Table of Comparison

| Feature | Batch Processing | Continuous Harvesting |

|---|---|---|

| Processing Method | Harvesting in discrete batches | Ongoing, non-stop harvesting |

| Efficiency | Lower, downtime between batches | Higher, constant operation |

| Harvest Quality | Consistent per batch | Variable but steady output |

| Labor Requirements | Intensive at intervals | Steady, less intense |

| Equipment Utilization | Periodic use, idle time present | Maximized, continuous use |

| Waste Generation | Higher, batch setup and cleanup | Lower, streamlined process |

| Suitable For | Seasonal crops, limited scale | Large scale, high volume operations |

Introduction to Harvesting Methods

Batch processing harvest involves collecting crops in discrete groups, allowing for controlled timing and quality assessment at each stage, which is ideal for fruits like apples and grapes. Continuous harvesting operates through ongoing, automated machinery that maximizes efficiency by processing crops such as lettuce or wheat without interruption, reducing labor costs and minimizing crop loss. Selecting between batch and continuous harvesting depends on crop type, field size, and desired product consistency.

What is Batch Processing in Gardening?

Batch processing in gardening refers to harvesting crops in specific groups or intervals rather than continuously picking produce as it ripens. This method allows gardeners to collect large quantities of fruits or vegetables at once, optimizing labor and reducing the frequency of harvesting activities. Batch processing is especially effective for crops that mature uniformly, ensuring maximum yield during a single harvest period.

Understanding Continuous Harvesting

Continuous harvesting enables the steady collection of crops, reducing labor peaks and increasing operational efficiency compared to batch processing. This method utilizes automated machinery to gather produce as it matures, minimizing crop spoilage and optimizing yield quality. Implementing continuous harvesting systems supports sustainable farming by maximizing resource use and decreasing post-harvest losses.

Key Differences Between Batch and Continuous Harvesting

Batch harvesting collects crops at specific intervals, allowing for controlled processing and quality assessment of each batch, which suits seasonal crops with uniform ripening. Continuous harvesting involves a steady, uninterrupted collection, maximizing efficiency and reducing labor costs, ideal for crops that mature gradually over time. Key differences include timing, equipment usage, labor intensity, and suitability for crop types, influencing operational decisions based on crop characteristics and resource availability.

Advantages of Batch Processing for Gardeners

Batch processing in harvesting allows gardeners to manage crops more efficiently by grouping plants based on maturity, which enhances quality control and reduces waste. This method enables targeted labor allocation, making it easier to plan and execute harvesting activities within optimal time frames. The controlled environment of batch harvesting helps maintain freshness and extends shelf life while simplifying post-harvest handling and storage.

Benefits of Continuous Harvesting in the Garden

Continuous harvesting in the garden enhances crop yield by allowing plants to produce steadily over a longer period, reducing waste and maximizing produce freshness. This method supports efficient resource use, as plants mature gradually and require less intensive labor compared to batch processing. Gardeners can enjoy a constant supply of fresh fruits and vegetables, optimizing nutritional value and minimizing storage needs.

Choosing the Best Harvesting Method for Your Crops

Batch processing harvests crops in discrete groups, allowing for precise quality control and minimized waste during peak ripeness. Continuous harvesting optimizes efficiency for high-volume crops by enabling a steady flow from field to storage, reducing labor costs and time delays. Selecting the best method depends on crop type, ripening uniformity, and operational scale to maximize yield and maintain produce quality.

Common Challenges with Batch vs Continuous Harvesting

Batch harvesting often faces challenges such as uneven crop maturity leading to inconsistent product quality and higher labor intensity during peak periods. Continuous harvesting requires advanced machinery and careful synchronization with planting schedules to avoid downtime and minimize crop loss. Both methods must address pest management and environmental impact while balancing operational costs and efficiency to optimize yield.

Tips for Transitioning Between Harvesting Methods

Transitioning from batch processing to continuous harvesting requires careful adjustment of timing and equipment calibration to maintain crop quality and reduce losses. Monitoring moisture levels and adjusting harvesting speeds ensures optimal efficiency and prevents damage during the continuous flow. Training staff on new operational protocols and implementing real-time data tracking enhances precision and adaptability throughout the transition.

Maximizing Yield: Combining Batch and Continuous Harvesting

Maximizing yield in harvesting requires integrating batch processing and continuous harvesting to optimize crop output and reduce losses. Batch processing allows for targeted harvesting at peak maturity, ensuring quality and minimizing waste, while continuous harvesting supports sustained collection suitable for high-volume operations. Combining these methods enhances overall efficiency and crop utilization by balancing precision and speed.

Batch processing vs continuous harvesting Infographic

gardendif.com

gardendif.com