Turning Pile vs Static Pile Illustration

Turning piles enhance composting by aerating the material, accelerating decomposition and reducing odors. Static piles require less labor but may decompose slower due to limited oxygen flow. Proper management of either method ensures rich, nutrient-dense compost ideal for soil improvement.

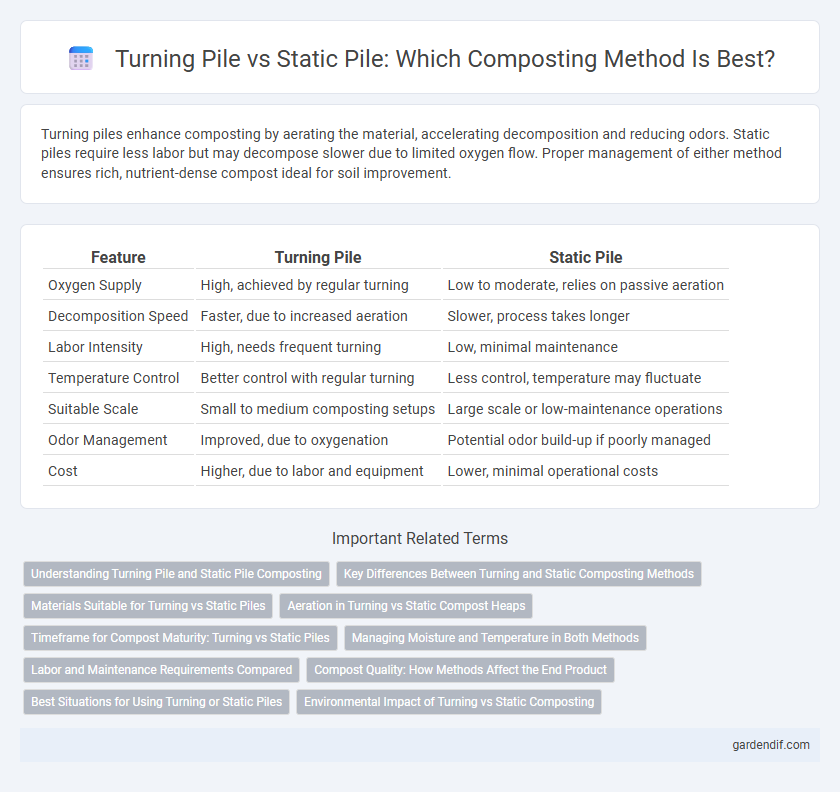

Table of Comparison

| Feature | Turning Pile | Static Pile |

|---|---|---|

| Oxygen Supply | High, achieved by regular turning | Low to moderate, relies on passive aeration |

| Decomposition Speed | Faster, due to increased aeration | Slower, process takes longer |

| Labor Intensity | High, needs frequent turning | Low, minimal maintenance |

| Temperature Control | Better control with regular turning | Less control, temperature may fluctuate |

| Suitable Scale | Small to medium composting setups | Large scale or low-maintenance operations |

| Odor Management | Improved, due to oxygenation | Potential odor build-up if poorly managed |

| Cost | Higher, due to labor and equipment | Lower, minimal operational costs |

Understanding Turning Pile and Static Pile Composting

Turning pile composting involves regularly aerating the organic material by physically turning it to enhance oxygen flow and accelerate decomposition. Static pile composting relies on passive aeration without turning, resulting in slower microbial activity but requiring less labor and equipment. Both methods effectively break down organic waste, with turning piles offering faster results and static piles being more suitable for larger or less intensive operations.

Key Differences Between Turning and Static Composting Methods

Turning piles involve regular aeration by physically mixing the compost, accelerating microbial activity and reducing composting time to 4-6 weeks. Static piles rely on passive aeration, requiring less labor but extending the decomposition period to several months and increasing the risk of anaerobic conditions. Temperature control in turning piles tends to be more consistent, promoting efficient organic matter breakdown compared to static piles.

Materials Suitable for Turning vs Static Piles

Turning piles are ideal for materials with higher moisture content and coarser textures, such as green yard waste, food scraps, and fresh manure, as frequent agitation promotes aeration and speeds up decomposition. Static piles suit more balanced, dry, and finely textured materials like wood chips, straw, and aged manure, where minimal disturbance prevents nutrient loss and maintains microbial stability. Selecting materials based on pile management optimizes composting efficiency and nutrient retention.

Aeration in Turning vs Static Compost Heaps

Turning compost piles improves aeration by regularly mixing materials, which enhances oxygen flow and accelerates microbial activity for faster decomposition. Static piles rely on passive aeration through natural airflow, which can create anaerobic zones if not managed properly, slowing down the composting process. Consistent turning prevents compaction, maintaining optimal oxygen levels essential for effective aerobic composting.

Timeframe for Compost Maturity: Turning vs Static Piles

Turning piles accelerate compost maturity by enhancing aeration and microbial activity, typically reducing the timeframe to 4-8 weeks compared to static piles. Static piles often require 3-6 months to reach full maturity due to limited oxygen diffusion and slower decomposition rates. Efficient moisture management and pile size also influence the overall composting duration in both methods.

Managing Moisture and Temperature in Both Methods

Turning piles promote aeration and uniform moisture distribution, preventing anaerobic conditions and overheating by regularly mixing organic material. Static piles rely on controlled moisture content and insulation to maintain consistent temperature and microbial activity, though they may require additional monitoring to avoid hotspots and drying. Effective management of moisture and temperature in both methods ensures optimal decomposition and odor control during composting.

Labor and Maintenance Requirements Compared

Turning piles require more labor due to the need for frequent aeration and mixing, which helps accelerate composting by maintaining optimal oxygen levels. Static piles demand less ongoing maintenance but may require additional management to prevent anaerobic conditions and odors. Both methods benefit from regular monitoring, but turning piles typically involve higher labor intensity and operational costs.

Compost Quality: How Methods Affect the End Product

Turning piles enhances aeration and microbial activity, resulting in a more uniform and nutrient-rich compost with balanced carbon-to-nitrogen ratios. Static piles may produce compost with uneven decomposition, sometimes leading to lower nutrient density and potential anaerobic zones that affect odor and quality. Consistent oxygen supply in turning piles accelerates organic matter breakdown, improving the final compost's texture and maturity.

Best Situations for Using Turning or Static Piles

Turning piles are best suited for small to medium-scale composting operations where frequent aeration accelerates decomposition and reduces odor. Static piles perform well in large-scale or low-maintenance settings, relying on passive aeration methods to minimize labor and machinery costs. Selecting between turning and static piles depends on factors like pile size, available labor, and desired composting speed.

Environmental Impact of Turning vs Static Composting

Turning piles enhances aerobic decomposition, reducing methane emissions commonly associated with static piles, which often experience anaerobic zones. Increased oxygen flow in turning piles accelerates organic matter breakdown, minimizing greenhouse gases and leachate production. Static composting, while less energy-intensive, may contribute to higher volatile organic compound release and slower pathogen reduction, impacting environmental safety.

Turning Pile vs Static Pile Infographic

gardendif.com

gardendif.com